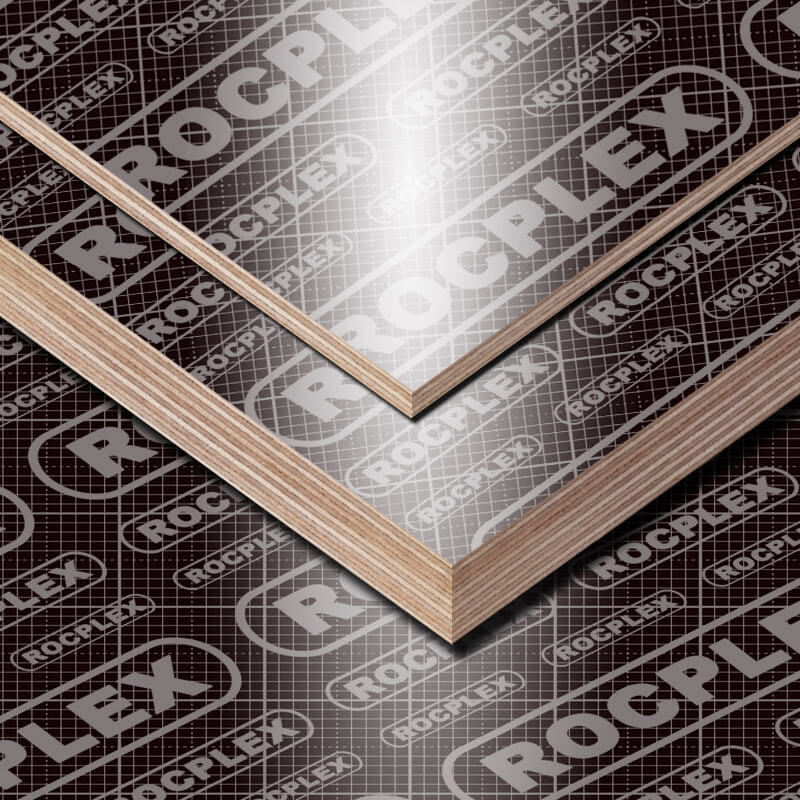

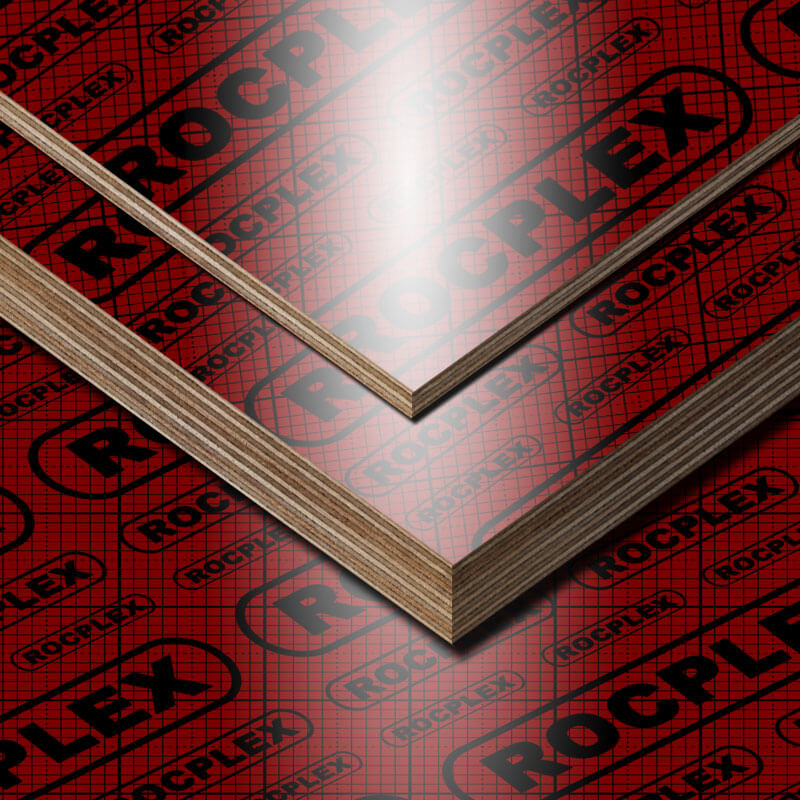

18mm ROCPLEX Film Faced Plywood For Construction Use Plywood Board

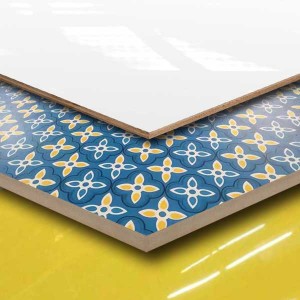

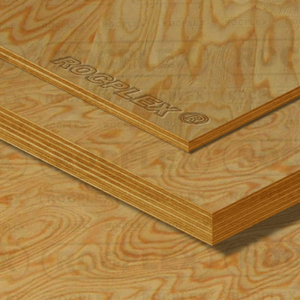

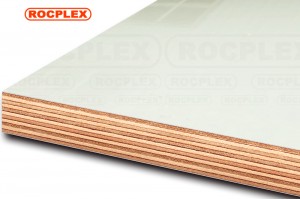

ROCPLEX ® 18mm Film Faced Plywood is engineered to provide top-notch performance in construction projects. Coated with a high-quality film, this plywood offers a smooth and durable surface ideal for concrete formwork. The 18mm thickness ensures robust support, making it suitable for demanding construction applications. Each panel is meticulously manufactured to meet high industry standards, ensuring consistent quality and reliability. The film-faced coating enhances its resistance to moisture and chemicals, ensuring longevity in tough construction environments.

This plywood is versatile and suitable for a wide range of formwork applications. Its robust construction and smooth surface make it easy to handle and install, reducing labor costs and improving job site efficiency. ROCPLEX 18mm Film Faced Plywood is also environmentally friendly, sourced from sustainable timber with low formaldehyde emissions, adhering to international environmental standards.

Ideal for building foundations, columns, walls, and beams, this plywood ensures a smooth finish and reliable performance. The film surface prevents concrete from sticking, facilitating easier formwork removal and protecting the concrete surface from damage.

With ROCPLEX 18mm Film Faced Plywood, you can achieve superior results in your construction projects. Its exceptional durability and performance make it the preferred choice for professionals in the construction industry.

|

Sr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

EN 322 |

7.5 |

Check out |

|

|

2 |

Density |

kg/m3 |

EN 323 |

690 |

Check out |

|

|

3 |

Bonding Qality |

Bonding Qality |

Mpa |

EN 314 |

Max: 1.68 Min: 0.81 |

Check out |

|

Damage Rate |

% |

85% |

Check out |

|||

|

4 |

Bending Moudulus of Elasticity |

Longitudinal |

Mpa |

EN 310 |

6997 |

Check out |

|

Lateral |

6090 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

59 |

Check out |

|

|

Lateral |

43.77 |

Check out |

||||

|

6 |

Cycle Life |

About 15-25 Repeated Using Times Acoording To Projects By Formwork Application |

||||

|

Sr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

EN 322 |

8 |

Check out |

|

|

2 |

Density |

kg/m3 |

EN 323 |

605 |

Check out |

|

|

3 |

Bonding Qality |

Bonding Qality |

Mpa |

EN 314 |

Max: 1.59 Min: 0.79 |

Check out |

|

Damage Rate |

% |

82% |

Check out |

|||

|

4 |

Bending Moudulus of Elasticity |

Longitudinal |

Mpa |

EN 310 |

6030 |

Check out |

|

Lateral |

5450 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

57.33 |

Check out |

|

|

Lateral |

44.79 |

Check out |

||||

|

6 |

Cycle Life |

About 12-20 Repeated Using Times Acoording To Projects By Formwork Application |

||||

|

Sr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

EN 322 |

8.4 |

Check out |

|

|

2 |

Density |

kg/m3 |

EN 323 |

550 |

Check out |

|

|

3 |

Bonding Qality |

Bonding Qality |

Mpa |

EN 314 |

Max: 1.40 Min: 0.70 |

Check out |

|

Damage Rate |

% |

74% |

Check out |

|||

|

4 |

Bending Moudulus of Elasticity |

Longitudinal |

Mpa |

EN 310 |

5215 |

Check out |

|

Lateral |

4796 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

53.55 |

Check out |

|

|

Lateral |

43.68 |

Check out |

||||

|

6 |

Cycle Life |

About 9-15 Repeated Using Times Acoording To Projects By Formwork Application |

||||

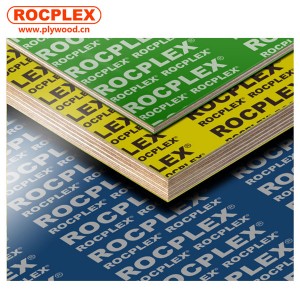

■ High Durability: Coated with a premium film for long-lasting performance.

■ Smooth Surface: Provides a flawless finish for concrete pouring.

■ Moisture Resistant: Film-faced coating protects against moisture and chemicals.

■ Versatile Applications: Suitable for foundations, walls, columns, beams, and more.

■ Easy Handling: Robust construction ensures ease of use and installation.

■ Eco-Friendly: Sourced from sustainable timber with low formaldehyde emissions.

■ Non-Stick Surface: Prevents sticking, facilitating easier formwork removal.

■ Consistent Quality: Manufactured to meet industry standards, ensuring reliability and performance.

■ Cost-Effective: Reduces labor and material costs with efficient performance and longevity.

|

ROCPLEX 18mm Film faced plywood Save cost |

||

|

|

Be special for phenolic glue and film |

The film faced plywood can be disassembled and used repeatedly for both faces,saving 25% of the cost. |

|

|

Optimization for the special grade of core |

|

|

|

Be special for adhesive |

|

|

ROCPLEX Film faced plywood Shorten duration |

||

|

|

Excellent effect of demoulding |

Shorten 30% of the duration. |

|

|

Avoid the reconstruction of the wall |

|

|

|

Be easy to incise and blend |

|

|

ROCPLEX Film faced plywood the high quality of casting |

||

|

|

The flat and smooth faces |

The faces are flat and smooth, avoiding bleeding out remains of bubbles and concrete. |

|

|

The structure of waterproof and breathability |

|

|

|

The edges are polished carefully |

|

|

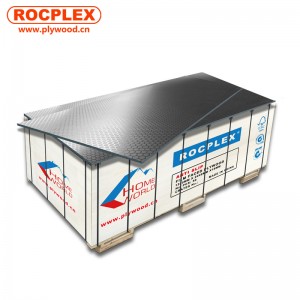

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

8 pallets |

22 CBM |

13000KGS |

12500KGS |

|

40 HQ |

18 pallets |

53 CBM |

27500KGS |

28000KGS |

ROCPLEX 18mm Film Faced Plywood is ideal for various concrete formwork applications, including foundations, walls, columns, and beams. This plywood provides a smooth and precise concrete surface, ensuring high-quality construction results. It is also suitable for bridge construction, tunnels, and other large infrastructure projects.

Beyond its primary use in concrete formwork, this plywood is perfect for other construction areas where a durable and reliable panel is required. Its moisture-resistant properties make it suitable for outdoor applications and environments exposed to harsh weather conditions.

ROCPLEX 18mm Film Faced Plywood is also used in residential and commercial building projects. Its strength and stability provide excellent support for various construction tasks, ensuring safety and structural integrity.

Reach out to us today to discover how ROCPLEX 18mm Film Faced Plywood can benefit your construction projects. Our experienced team is ready to provide high-quality plywood solutions tailored to your needs.