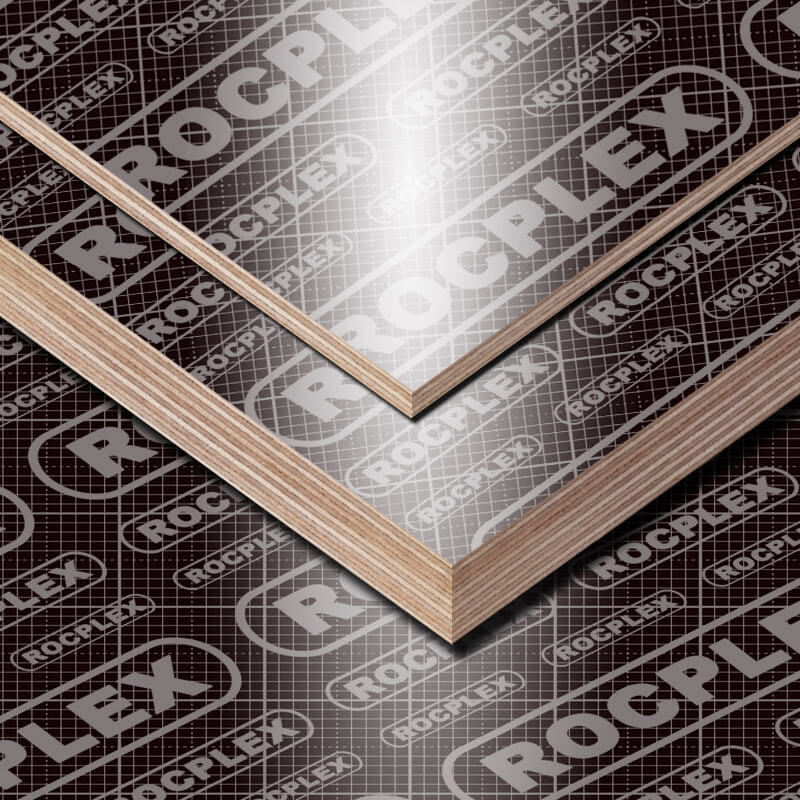

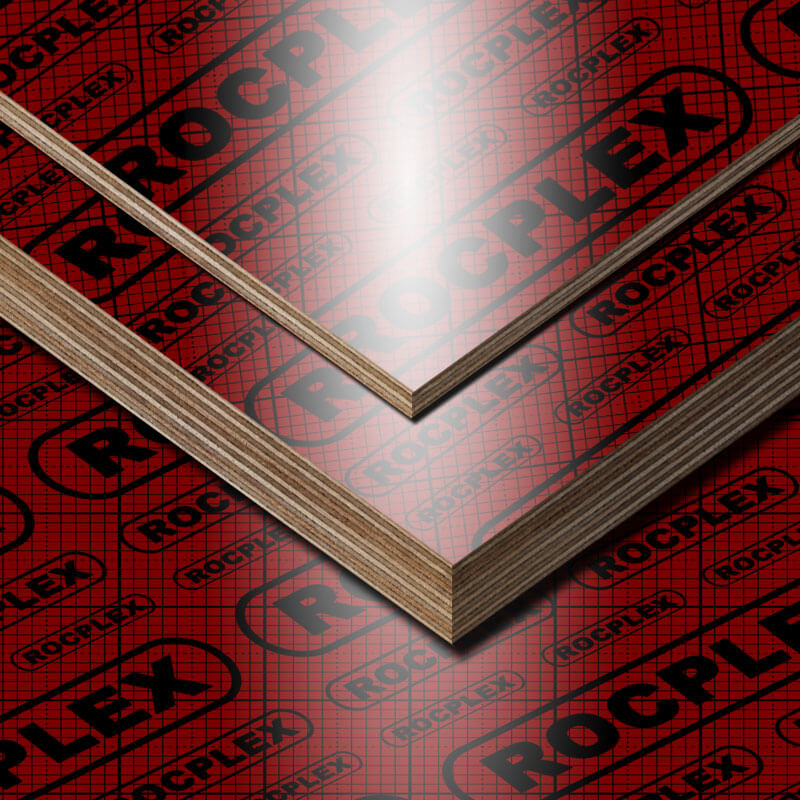

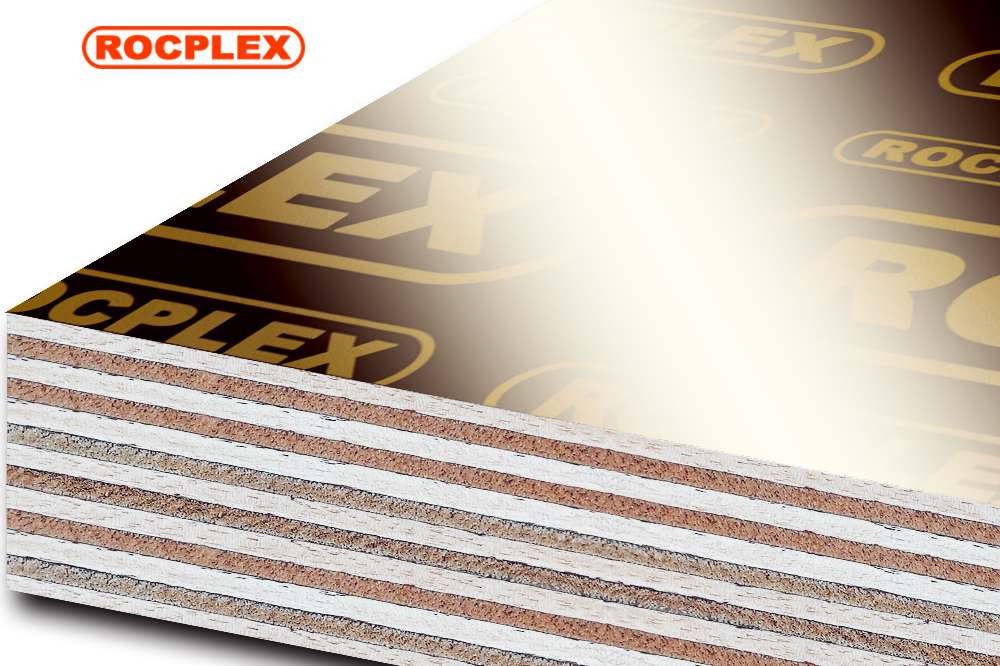

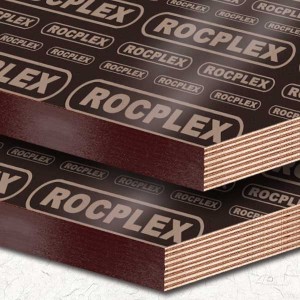

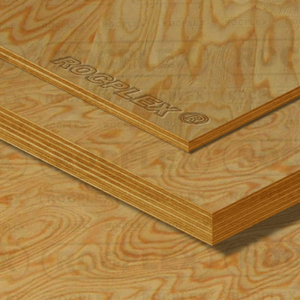

Brown Film Faced Plywood 25mm For Construction Use Shuttering Plywood Sheet

ROCPLEX ® Brown Film Faced Plywood 25mm is specifically engineered for construction use, providing a robust and durable solution for formwork and other demanding applications. The brown film faced surface enhances its resistance to water, abrasion, and chemicals, making it suitable for various construction environments.

With a thickness of 25mm, this plywood offers exceptional strength and stability, ensuring it can withstand heavy loads and high-pressure conditions. The film facing creates a smooth, non-stick surface that facilitates easy removal of concrete forms and reduces labor costs.

ROCPLEX ensures that every sheet of brown film faced plywood undergoes stringent quality control processes. This guarantees consistent performance and longevity, even in the most challenging conditions. The plywood is constructed using high-quality veneers bonded with waterproof adhesive, enhancing its structural integrity and resistance to delamination.

The brown film faced plywood is versatile and can be used in multiple construction applications, including flooring, walls, roofing, and temporary structures. Its superior quality and reliability make it a preferred choice for contractors and builders seeking durable and efficient formwork solutions.

|

Sr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

EN 322 |

7.5 |

Check out |

|

|

2 |

Density |

kg/m3 |

EN 323 |

690 |

Check out |

|

|

3 |

Bonding Qality |

Bonding Qality |

Mpa |

EN 314 |

Max: 1.68 Min: 0.81 |

Check out |

|

Damage Rate |

% |

85% |

Check out |

|||

|

4 |

Bending Moudulus of Elasticity |

Longitudinal |

Mpa |

EN 310 |

6997 |

Check out |

|

Lateral |

6090 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

59 |

Check out |

|

|

Lateral |

43.77 |

Check out |

||||

|

6 |

Cycle Life |

About 15-25 Repeated Using Times Acoording To Projects By Formwork Application |

||||

|

Sr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

EN 322 |

8 |

Check out |

|

|

2 |

Density |

kg/m3 |

EN 323 |

605 |

Check out |

|

|

3 |

Bonding Qality |

Bonding Qality |

Mpa |

EN 314 |

Max: 1.59 Min: 0.79 |

Check out |

|

Damage Rate |

% |

82% |

Check out |

|||

|

4 |

Bending Moudulus of Elasticity |

Longitudinal |

Mpa |

EN 310 |

6030 |

Check out |

|

Lateral |

5450 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

57.33 |

Check out |

|

|

Lateral |

44.79 |

Check out |

||||

|

6 |

Cycle Life |

About 12-20 Repeated Using Times Acoording To Projects By Formwork Application |

||||

|

Sr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

EN 322 |

8.4 |

Check out |

|

|

2 |

Density |

kg/m3 |

EN 323 |

550 |

Check out |

|

|

3 |

Bonding Qality |

Bonding Qality |

Mpa |

EN 314 |

Max: 1.40 Min: 0.70 |

Check out |

|

Damage Rate |

% |

74% |

Check out |

|||

|

4 |

Bending Moudulus of Elasticity |

Longitudinal |

Mpa |

EN 310 |

5215 |

Check out |

|

Lateral |

4796 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

53.55 |

Check out |

|

|

Lateral |

43.68 |

Check out |

||||

|

6 |

Cycle Life |

About 9-15 Repeated Using Times Acoording To Projects By Formwork Application |

||||

■ High Durability: Brown film facing enhances resistance to wear and chemicals.

■ Water Resistance: Suitable for wet conditions, ensuring long-lasting performance.

■ Exceptional Strength: 25mm thickness provides stability and support.

■ Smooth Surface: Facilitates easy removal of concrete forms, reducing labor costs.

■ Quality Control: Ensures consistent performance and longevity.

■ Versatile Applications: Ideal for flooring, walls, roofing, and temporary structures.

■ Structural Integrity: High-quality veneers and waterproof adhesive prevent delamination.

■ Reliability: Trusted by contractors for demanding construction projects.

■ Efficiency: Smooth surface finish improves overall project efficiency.

|

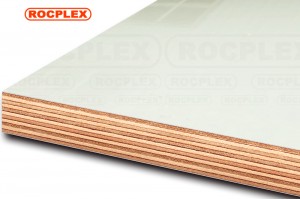

ROCPLEX 18mm Film faced plywood Save cost |

||

|

|

Be special for phenolic glue and film |

The film faced plywood can be disassembled and used repeatedly for both faces,saving 25% of the cost. |

|

|

Optimization for the special grade of core |

|

|

|

Be special for adhesive |

|

|

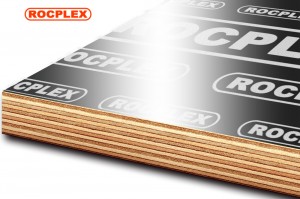

ROCPLEX Film faced plywood Shorten duration |

||

|

|

Excellent effect of demoulding |

Shorten 30% of the duration. |

|

|

Avoid the reconstruction of the wall |

|

|

|

Be easy to incise and blend |

|

|

ROCPLEX Film faced plywood the high quality of casting |

||

|

|

The flat and smooth faces |

The faces are flat and smooth, avoiding bleeding out remains of bubbles and concrete. |

|

|

The structure of waterproof and breathability |

|

|

|

The edges are polished carefully |

|

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

8 pallets |

22 CBM |

13000KGS |

12500KGS |

|

40 HQ |

18 pallets |

53 CBM |

27500KGS |

28000KGS |

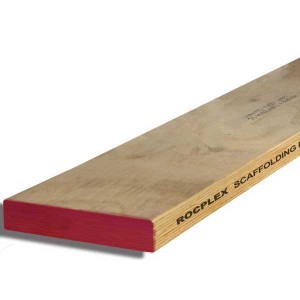

ROCPLEX Brown Film Faced Plywood 25mm is ideal for use in concrete formwork, providing a sturdy and reliable mold for concrete shapes. Its water and abrasion resistance make it suitable for use in harsh and wet conditions, ensuring long-term performance.

This plywood is also perfect for flooring applications, offering durability and stability. It can be used for wall and roof structures, providing strength and resistance to environmental factors. The smooth film surface ensures a high-quality finish, beneficial for precise construction projects.

ROCPLEX Brown Film Faced Plywood can be employed in temporary structures and scaffolding, providing a robust and reliable base.

Choose ROCPLEX Brown Film Faced Plywood 25mm for your construction projects. Contact us today to place your order and ensure the durability and reliability of your formwork solutions.