A Versatile Building Material for the Construction Industry – ROCPLEX Finished Plywood

In today's construction industry, the demand for high-quality, versatile, and sustainable building materials is at an all-time high. One such product that has been gaining popularity among architects, contractors, and builders is ROCPLEX finished plywood. In this article, we will delve into the features, benefits, and uses of ROCPLEX finished plywood.

UV finished Plywood Types:

White Birch – Red Oak – White Maple – Cherry – Walnut – Clear Alder – Pine

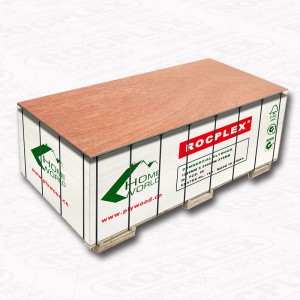

ROCPLEX Plywood Provide at a competitive price and stable quality!.

Please contact our sales team for more detailed information regarding finish plywood, Finished Plywood, ROCPLEX finished plywood.

What is Finished Plywood?

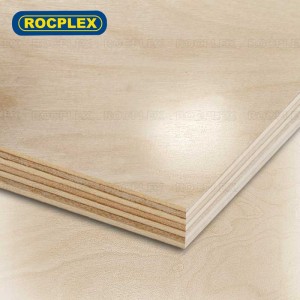

ROCPLEX finished plywood is a premium-quality plywood that is manufactured using state-of-the-art technology. It is made from 100% hardwood veneers that are cross-laminated to provide a stable and consistent panel. The unique manufacturing process used to create ROCPLEX finished plywood gives the product a smooth and uniform surface that is ready to be finished with paint or another coating.

Advantage of Using ROCPLEX Finished Plywood

Durability: The hardwood veneers used to manufacture ROCPLEX finished plywood provide superior durability and resistance to moisture, abrasion, and impact. This makes it ideal for use in a variety of building applications where panels are subjected to high levels of wear and tear.

Consistent Quality: The cross-lamination process used to manufacture ROCPLEX finished plywood ensures that every panel is consistent in quality, thickness, and density. This provides architects, engineers, and contractors with a product that they can depend on to perform consistently and reliably.

Versatility: ROCPLEX finishe plywood can be used in a variety of applications, including wall and ceiling panels, flooring, cabinetry, and furniture. Its smooth and uniform surface makes it ideal for use as a substrate for paint, stain, or another coating, allowing for a wide range of design options.

Sustainable: ROCPLEX finished plywood is made from 100% hardwood veneers, making it an environmentally friendly choice for the construction industry. The use of hardwoods from responsibly managed forests helps to reduce the impact of the construction industry on the environment.

How to use ROCPLEX Finished Plywood

Wall and Ceiling Panels: The smooth and uniform surface of ROCPLEX finished plywood makes it ideal for use as wall and ceiling panels in both residential and commercial buildings. Its durability and resistance to moisture and abrasion make it ideal for use in high-traffic areas, such as kitchens, bathrooms, and entryways.

Flooring: ROCPLEX finishe plywood can be used as a substrate for flooring in both residential and commercial buildings. Its durability and resistance to moisture and abrasion make it ideal for use in high-traffic areas, such as kitchens, bathrooms, and entryways.

Cabinetry and Furniture: The smooth and uniform surface of ROCPLEX finished plywood makes it ideal for use in the manufacture of cabinetry and furniture. Its durability and resistance to moisture and abrasion make it ideal for use in high-use areas, such as kitchens and bathrooms.

ROCPLEX finished plywood is a premium-quality, versatile, and sustainable building material that is ideal for a wide range of construction applications. Its durability, consistent quality, and smooth and uniform surface make it a popular choice among architects, engineers, contractors, and builders. With its environmental sustainability and range of design options, ROCPLEX finished plywood is a product that offers both performance and style.