Film Faced Plywood High Quality for Waterproof Black Film Faced Plywood Concrete Formwork Shuttering Marine Plywood

Every single member from our large efficiency revenue team values customers' wants and company communication for Film Faced Plywood High Quality for Waterproof Black Film Faced Plywood Concrete Formwork Shuttering Marine Plywood, We welcome clients everywhere in the word to make contact with us for foreseeable future company relationships. Our goods are the best. Once Selected, Ideal Forever!

Every single member from our large efficiency revenue team values customers' wants and company communication for Film Faced Plywood, Plywood, ROCPLEX Film Faced Plywood, In the new century, we promote our enterprise spirit "United, diligent, high efficiency, innovation", and stick to our policy"basing on quality, be enterprising, striking for first class brand". We would take this golden opportunity to create bright future.

|

Sr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

EN 322 |

8.4 |

Check out |

|

|

2 |

Density |

kg/m3 |

EN 323 |

550 |

Check out |

|

|

3 |

Bonding Qality |

Bonding Qality |

Mpa |

EN 314 |

Max: 1.40 Min: 0.70 |

Check out |

|

Damage Rate |

% |

74% |

Check out |

|||

|

4 |

Bending Moudulus of Elasticity |

Longitudinal |

Mpa |

EN 310 |

5215 |

Check out |

|

Lateral |

4796 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

53.55 |

Check out |

|

|

Lateral |

43.68 |

Check out |

||||

|

6 |

Cycle Life |

About 9-15 Repeated Using Times Acoording To Projects By Formwork Application |

||||

|

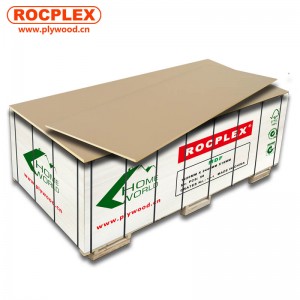

ROCPLEX 15mm Film faced plywood Save cost |

||

|

Be special for phenolic glue and film |

The film faced plywood can be disassembled and used repeatedly for both faces,saving 25% of the cost. |

|

|

Optimization for the special grade of core |

||

|

Be special for adhesive |

||

|

ROCPLEX Film faced plywood Shorten duration |

||

|

Excellent effect of demoulding |

Shorten 30% of the duration. |

|

|

Avoid the reconstruction of the wall |

||

|

Be easy to incise and blend |

||

|

ROCPLEX Film faced plywood the high quality of casting |

||

|

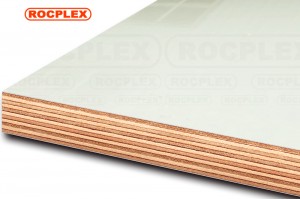

The flat and smooth faces |

The faces are flat and smooth, avoiding bleeding out remains of bubbles and concrete. |

|

|

The structure of waterproof and breathability |

||

|

The edges are polished carefully |

||

|

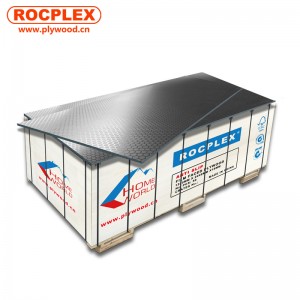

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

8 pallets |

22 CBM |

13000KGS |

12500KGS |

|

40 HQ |

18 pallets |

53 CBM |

27500KGS |

28000KGS |

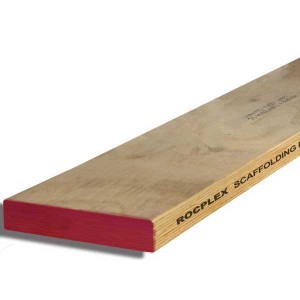

Meanwhile we also can supply you the formwork systerm accessories, commercial plywood , film faced plywood etc.

We specially professional in supplying antislip plywood.

Please contact our sales team for more detailed information regarding chinese film faced plywood.

Each member of the ROCPLEX team attaches importance to customer needs and efficient communication, and prepares Film Faced Plywood High Quality for Waterproof Black Film Faced Plywood Concrete Formwork Shuttering Marine Plywood for customers. We welcome you to contact us to establish a foreseeable future company relationship. Our film faced plywood is the best. Choosing ROCPLEX is choosing quality and guarantee!

Film Faced Plywood, Plywood, ROCPLEX Film Faced Plywood, we will continue to carry forward the enterprise spirit of "unity, diligence, efficiency and innovation", and adhere to the policy of "based on quality, forge ahead, and strive to create a first-class brand".

Film faced plywood may account for nearly half of the cost of concrete formwork structure. For cost-effective buildings, contractors should consider the maximum benefits of multi-purpose nuclear power when selecting film faced plywood.

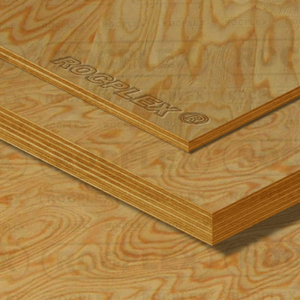

ROCPLEX film faced plywood, smooth on both sides, durable and durable, suitable for the needs of different building templates. Compared with traditional plywood, ROCPLEX can be reused and provides high-quality as-faced concrete finish.

ROCPLEX − member manufacturers of the Engineering Wood Association produce a variety of plywood products. ROCPLEX film faced plywood is designed for most general concrete molding applications. ROCPLEX brand film coating increases the stability of formwork plywood, resists abrasion, and provides a smoother and more durable molding surface.

Each manufacturer of covered concrete molding panel provides proprietary products, providing various functions and advantages.