Film Faced Plywood

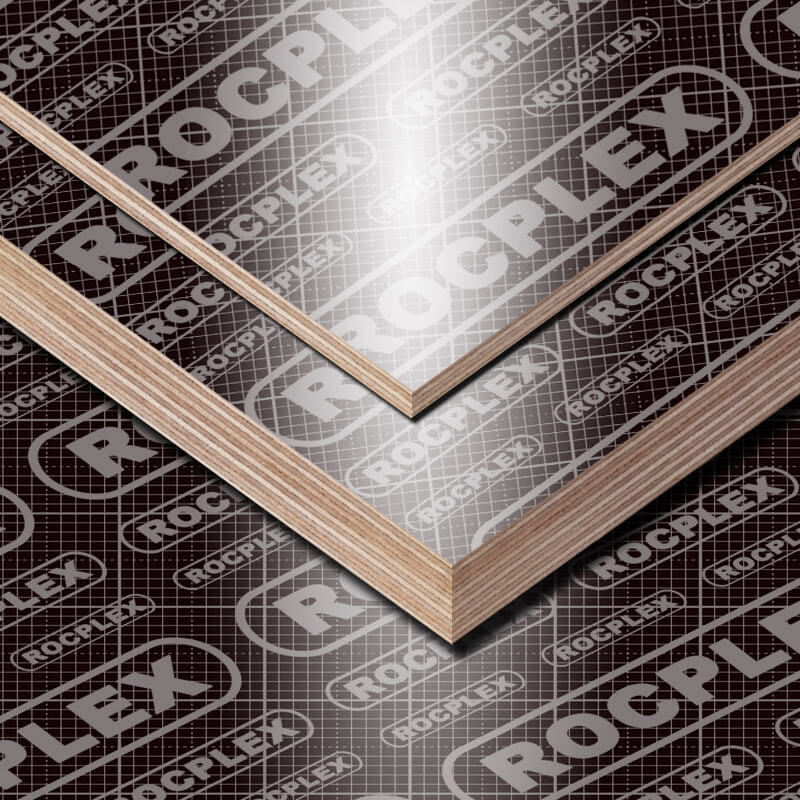

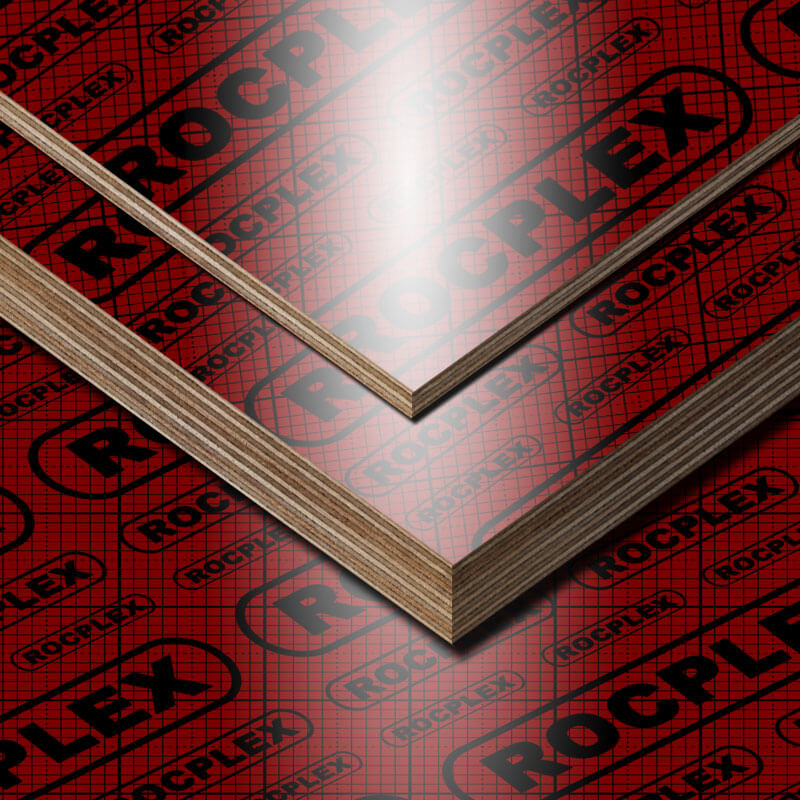

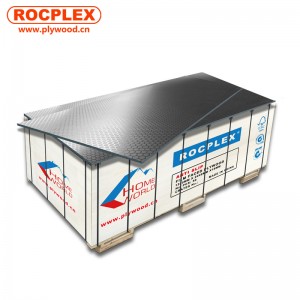

ROCPLEX ® Film Faced Plywood is a premium product designed to meet the rigorous demands of construction projects. This plywood is manufactured using high-quality veneers bonded with phenolic resin, ensuring excellent durability and water resistance. The film-faced surface provides a smooth finish, making it ideal for concrete formwork.

Each sheet of ROCPLEX Film Faced Plywood undergoes strict quality control to ensure consistency and reliability. The phenolic film overlay is resistant to wear, impact, and moisture, making it suitable for multiple uses in harsh environments. This plywood is available in various thicknesses to suit different structural requirements.

The edges of ROCPLEX Film Faced Plywood are sealed with water-resistant paint to prevent moisture ingress, enhancing its longevity. This feature makes it particularly suitable for outdoor and wet conditions, providing a dependable solution for construction needs.

ROCPLEX Film Faced Plywood is designed to offer high mechanical strength and dimensional stability. It performs excellently under heavy loads, making it an ideal choice for load-bearing applications in construction and other industrial uses.

|

Sr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

EN 322 |

7.5 |

Check out |

|

|

2 |

Density |

kg/m3 |

EN 323 |

690 |

Check out |

|

|

3 |

Bonding Qality |

Bonding Qality |

Mpa |

EN 314 |

Max: 1.68 Min: 0.81 |

Check out |

|

Damage Rate |

% |

85% |

Check out |

|||

|

4 |

Bending Moudulus of Elasticity |

Longitudinal |

Mpa |

EN 310 |

6997 |

Check out |

|

Lateral |

6090 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

59 |

Check out |

|

|

Lateral |

43.77 |

Check out |

||||

|

6 |

Cycle Life |

About 15-25 Repeated Using Times Acoording To Projects By Formwork Application |

||||

|

Sr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

EN 322 |

8 |

Check out |

|

|

2 |

Density |

kg/m3 |

EN 323 |

605 |

Check out |

|

|

3 |

Bonding Qality |

Bonding Qality |

Mpa |

EN 314 |

Max: 1.59 Min: 0.79 |

Check out |

|

Damage Rate |

% |

82% |

Check out |

|||

|

4 |

Bending Moudulus of Elasticity |

Longitudinal |

Mpa |

EN 310 |

6030 |

Check out |

|

Lateral |

5450 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

57.33 |

Check out |

|

|

Lateral |

44.79 |

Check out |

||||

|

6 |

Cycle Life |

About 12-20 Repeated Using Times Acoording To Projects By Formwork Application |

||||

|

Sr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

EN 322 |

8.4 |

Check out |

|

|

2 |

Density |

kg/m3 |

EN 323 |

550 |

Check out |

|

|

3 |

Bonding Qality |

Bonding Qality |

Mpa |

EN 314 |

Max: 1.40 Min: 0.70 |

Check out |

|

Damage Rate |

% |

74% |

Check out |

|||

|

4 |

Bending Moudulus of Elasticity |

Longitudinal |

Mpa |

EN 310 |

5215 |

Check out |

|

Lateral |

4796 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

53.55 |

Check out |

|

|

Lateral |

43.68 |

Check out |

||||

|

6 |

Cycle Life |

About 9-15 Repeated Using Times Acoording To Projects By Formwork Application |

||||

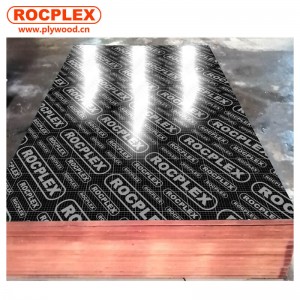

■ Durability: ROCPLEX Film Faced Plywood is made from high-quality veneers and phenolic resin, providing exceptional strength and durability.

■ Water Resistance: The phenolic film overlay and sealed edges ensure excellent water resistance, making it suitable for outdoor and wet conditions.

■ Smooth Surface: The film-faced surface provides a smooth finish, ideal for concrete formwork and other applications requiring a clean, uniform surface.

■ High Strength: This plywood offers high mechanical strength and dimensional stability, performing well under heavy loads and in demanding environments.

■ Versatility: Suitable for various applications, including construction, furniture making, industrial uses, and marine environments.

■ Longevity: Designed for multiple uses, ROCPLEX Film Faced Plywood maintains its integrity and performance over time, providing a cost-effective solution for long-term projects.

■ Easy Handling: Available in various thicknesses and sizes, this plywood is easy to handle and install, saving time and effort on construction sites.

■ Quality Assurance: Each sheet undergoes strict quality control to ensure consistency, reliability, and superior performance.

|

ROCPLEX Film faced plywood Save cost |

||

|

|

Be special for phenolic glue and film |

The film faced plywood can be disassembled and used repeatedly for both faces,saving 25% of the cost. |

|

|

Optimization for the special grade of core |

|

|

|

Be special for adhesive |

|

|

ROCPLEX Film faced plywood Shorten duration |

||

|

|

Excellent effect of demoulding |

Shorten 30% of the duration. |

|

|

Avoid the reconstruction of the wall |

|

|

|

Be easy to incise and blend |

|

|

ROCPLEX Film faced plywood the high quality of casting |

||

|

|

The flat and smooth faces |

The faces are flat and smooth, avoiding bleeding out remains of bubbles and concrete. |

|

|

The structure of waterproof and breathability |

|

|

|

The edges are polished carefully |

|

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

8 pallets |

22 CBM |

13000KGS |

12500KGS |

|

40 HQ |

18 pallets |

53 CBM |

27500KGS |

28000KGS |

ROCPLEX Film Faced Plywood is versatile and widely used in construction for concrete formwork. Its water-resistant properties make it ideal for outdoor applications, providing a durable and reliable formwork solution.

In addition to construction, this plywood is used in making furniture and cabinets where a smooth, durable surface is required. Its aesthetic appeal and durability make it a preferred choice for high-quality furniture.

This plywood is also suitable for industrial applications such as creating durable packing cases and pallets. Its high strength and resistance to wear ensure that it can withstand the rigors of transportation and handling.

ROCPLEX Film Faced Plywood can be used in marine environments for boat building and dock construction. Its water-resistant properties make it an excellent material for these applications, ensuring long-lasting performance even in wet conditions.

Contact us today to learn more about ROCPLEX Film Faced Plywood and how it can benefit your construction and industrial projects. Our team is ready to assist you in choosing the right specifications for your needs.