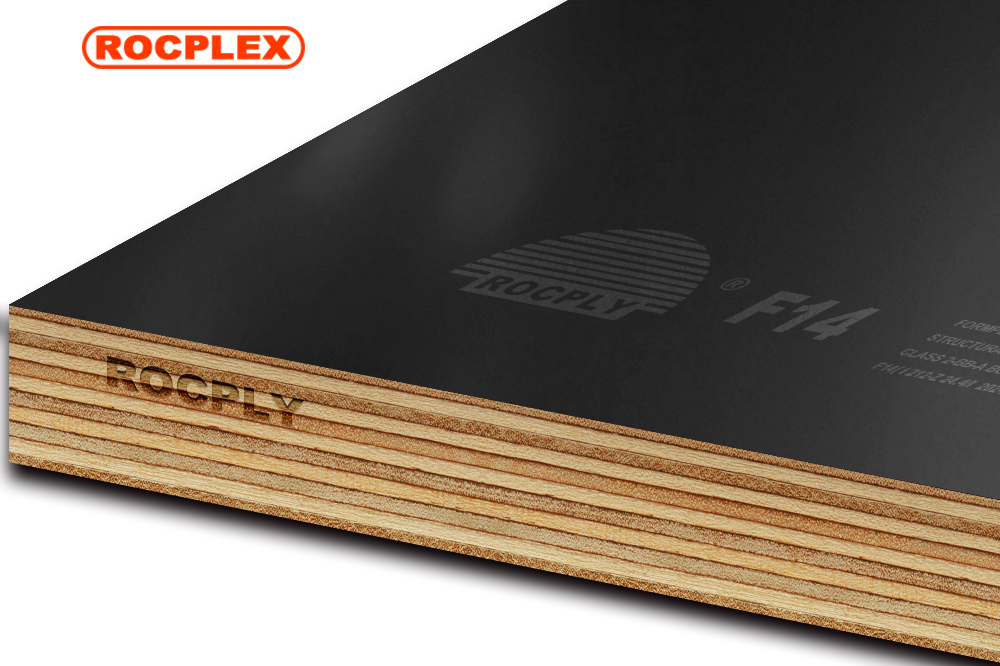

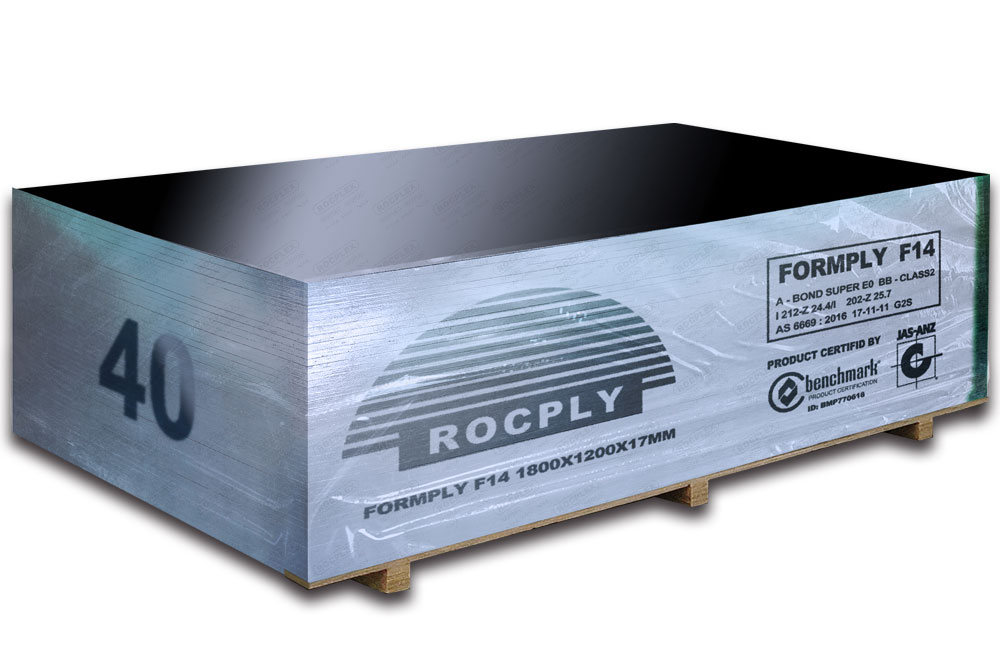

Formply F14 1800 x 1200 x 17mm Formwork Plywood AS 6669 Certified

ROCPLY ® Formply F14 1800 x 1200 x 17mm is specifically designed to provide exceptional performance in formwork applications. This plywood meets AS 6669 standards, ensuring it can handle the rigorous demands of concrete forming.

The phenolic resin overlay on ROCPLY Formply F14 provides a smooth and durable surface, reducing the need for additional finishing. The F14 grade ensures the plywood can withstand heavy loads and repeated use in construction environments.

Produced from sustainably sourced timber, ROCPLY Formply F14 is both environmentally friendly and economically viable. The 1800 x 1200 x 17mm dimensions make it suitable for a variety of construction projects, offering versatility and reliable performance.

ROCPLY Formply F14 is treated to resist moisture and fungal attacks, ensuring a longer lifespan even in harsh conditions. This makes ROCPLY Formply F14 an excellent choice for long-term construction projects, reducing the need for frequent replacements.

ROCPLY Formply F14 is also easy to handle and install, with uniform thickness and smooth edges that facilitate quick and efficient setup on-site.

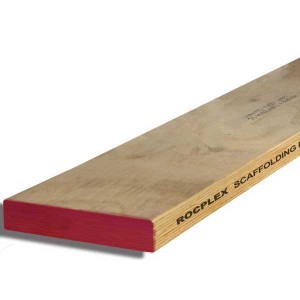

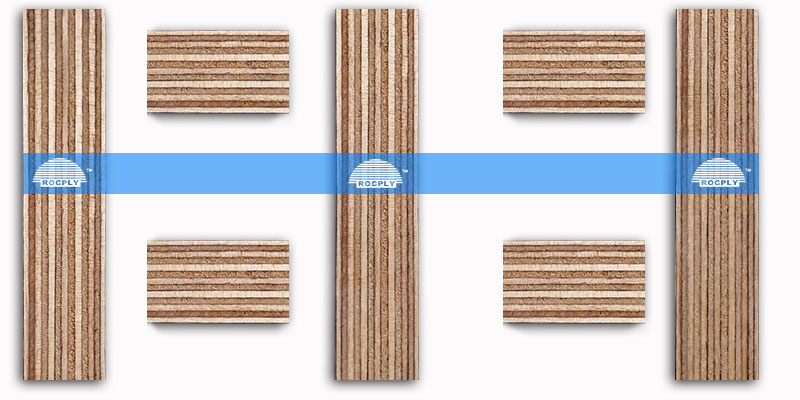

ROCPLY formply plywood for strong, stable, concrete formwork

| Stress Grade | Sheet Size (mm) | Thicknesses (mm) | Weight (kg/sheet) | Parallel to face grain | Perpendicular to face grain | Core

Materials |

Packing

Unit (sheets) |

||

| Momentof inertia | Sectionmodulus | Momentof inertia | Sectionmodulus | ||||||

| I(mm4/mm) | Z(mm3/mm) | I(mm4/mm) | Z(mm3/mm) | ||||||

| F17 SENSO | 1800×1200 | 12, 17, 19 & 25 | 24 | 240.0 | 27.6 | 178.0 | 22.9 | Full hardwood | 40 / 43 |

| F17 SNESO | 2400×1200 | 12, 17, 19 & 25 | 32 | 240.0 | 27.6 | 178.0 | 22.9 | Full hardwood | 40 / 43 |

Surfaces

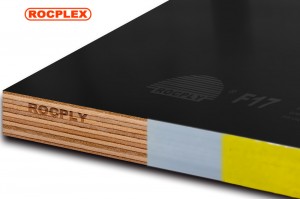

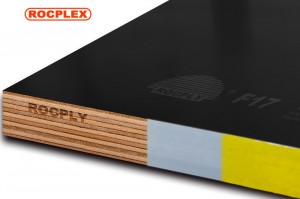

ROCPLY Special Custom HDO Film Facing Does Not Absorb Water.

And It Does Not Swell Or Shrink.

The Robust, Smooth Surface Guarantees First-class Concrete Quality Even After Many Uses.

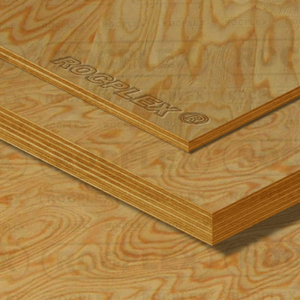

Structureur

Manufactured From High-grade Full hardwood Veneers Bonded Together With Super E0 Waterproof Adhesive, Which Has Superior Bond Strength.

The Oblique Jiont And Hot-melt Splicing Technology Are Used To Avoid Every Possible Gap.

To Ensure Excellent Hardness And Stability.

Bonding

Super E0 Waterproof Adhesive. If Put In Boiling Water For 72 Hours, It Is Still Glue-sticking And Non Deformed.

Sealing

The Edges 4 Times Sealed With Waterproof Paint In The Factory For Minimise Moisture Penetration.

|

1 |

Face and Back |

ROCPLY Special Custom Film |

|

2 |

Grade |

AA garde |

|

3 |

Core Materials |

Full Hardwood Core |

|

4 |

Glue Choose |

A bond Waterproof Super E0 Glue |

|

5 |

Thickness |

6-28mm(normal thickness:12mm, 15mm, 18mm, 21mm) |

|

6 |

Specification |

1800mmX1200mm, 2400mmX1200mm 1800mmX600mm , 2400mmX600mm |

|

7 |

Moisture Content |

8-14% |

|

8 |

Density |

730-780 kg/ m3 |

■ AS 6669 Certified: Meets industry standards for formwork plywood.

■ High Strength: F14 grade offers superior load-bearing capacity.

■ Phenolic Resin Overlay: Smooth surface reduces the need for additional finishing.

■ Moisture and Fungal Resistance: Treated for durability in tough conditions.

■ Sustainable Timber: Produced from responsibly sourced wood.

■ versatile Dimensions: 1800 x 1200 x 17mm for various applications.

■ Easy Installation: Uniform thickness and smooth edges facilitate handling.

■ Economical: Durable and reusable, lowering project costs.

Enhance your construction projects with ROCPLY Formply F14 1800 x 1200 x 17mm. Contact us now to order and benefit from the high quality and performance of our AS 6669 certified formwork plywood.

| ROCPLY Fomply Save cost | ||

| Be special for phenolic glue and film | The formply can be disassembled and used repeatedly for both faces,saving 25% of the cost. | |

| Optimization for the special grade of core | ||

| Be special for adhesive | ||

| ROCPLY Fomply Shorten duration | ||

| Excellent effect of demoulding | Shorten 30% of the duration. | |

| Avoid the reconstruction of the wall | ||

| Be easy to incise and blend | ||

| ROCPLY Formply The high quality of casting | ||

| The flat and smooth faces | The faces are flat and smooth, avoiding bleeding out remains of bubbles and concrete. | |

| The structure of waterproof and breathability | ||

| The edges are polished carefully | ||

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

10-12 pallets |

22 CBM |

13000KGS |

12500KGS |

|

40 HQ |

20-27 pallets |

43 CBM |

25500KGS |

26000KGS |