Formply F17 Massive Selection for China Structural Plywood F17 Formply for Australia with Benchmark Certification

We are going to dedicate ourselves to providing our esteemed buyers together with the most enthusiastically thoughtful products and services for Formply F17 Massive Selection for China Structural Plywood F17 Formply for Australia with Benchmark Certification, We glance ahead to determine a long-term organization marriage together with your esteem co-operation.

We are going to dedicate ourselves to providing our esteemed buyers together with the most enthusiastically thoughtful products and services for F17 formply, Formply, Formply F17, If you need any of our merchandise, or have other products to be produced, be sure to send us your inquiries, samples or comprehensive drawings. Meanwhile, aiming to develop into an international enterprise group, we look forward to receiving offers for joint ventures and other cooperative projects.

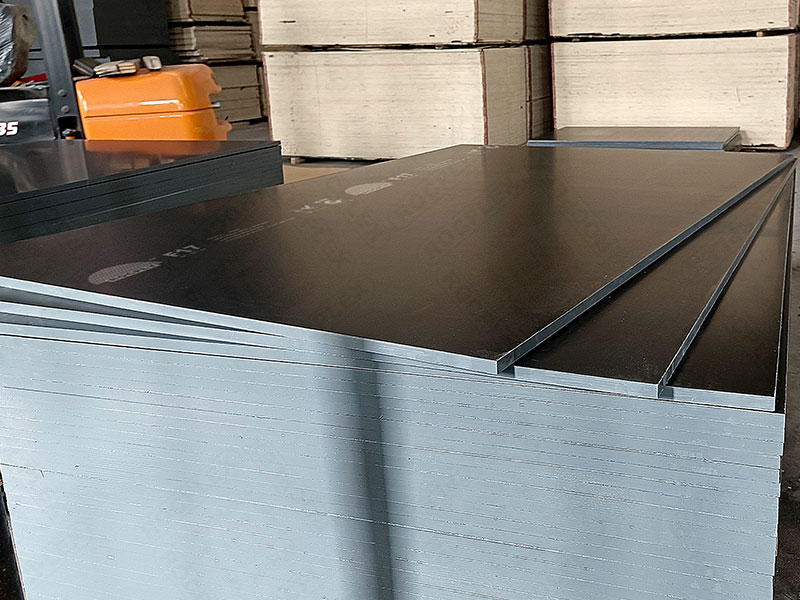

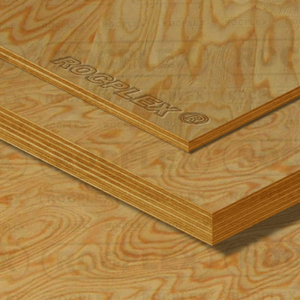

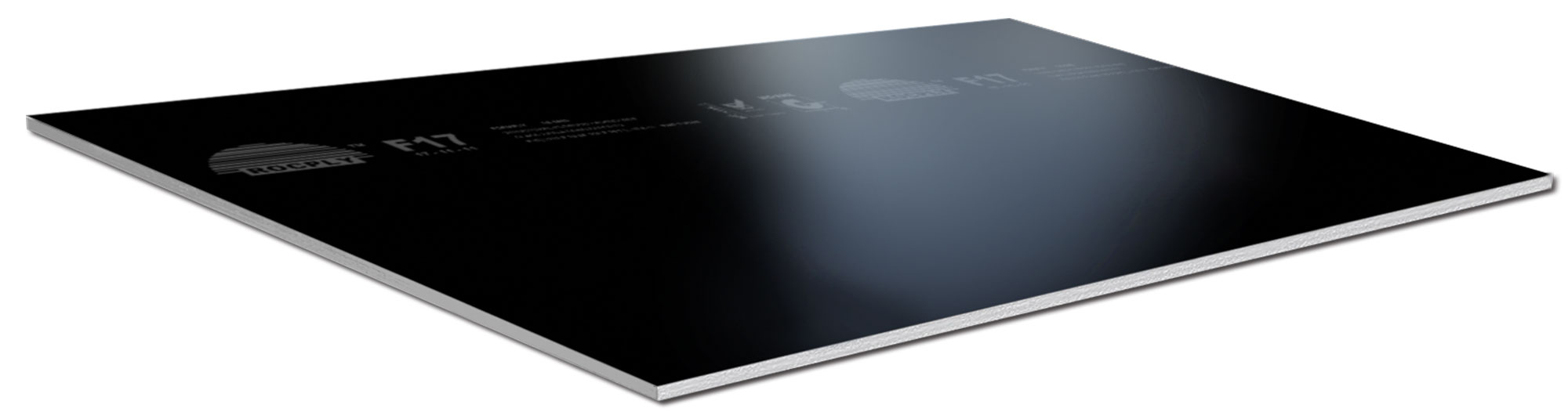

ROCPLY TM F17 Formply is plywood made with a high-density overlay (HDO) of Phenolic resin infused paper bond to give you an amazing off form finish and it’s structural integrity allows multiple reuses across the Concrete, Building and Construction Industries.

ROCPLY F17 Formply for strong, stable, concrete formwork

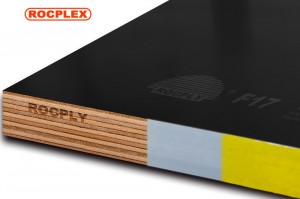

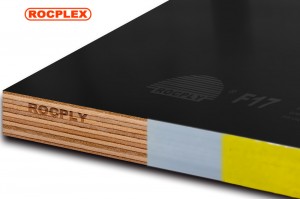

Manufactured From High-grade Full Hardwood Veneers Bonded Together With Custom Made Super E0 Waterproof Adhesive, Which Has Superior Bond Strength.

The oblique jiont and hot-melt splicing technology are used to avoid every possible gap.

ROCPLY Formply is a high quality formwork plywood developed and engineered specifically for the Australian market.

With a three tier quality control program comprising;

AA detailed ‘Manufacturing Specification’ adhered to by trained staff;

Regular, detailed and recorded in house testing on key quality requirements and independent grading,

Testing and certification carried out by Certemark Iternational (CMI) and DNV.

ROCPLY Formply provides assurance of quality and consistency.

All veneer in the manufacture is certified Forest Stewardship Council (FSC) from sustainable forests.

ROCPLY formply plywood for strong, stable, concrete formwork

| Stress Grade | Sheet Size (mm) | Thicknesses (mm) | Weight (kg/sheet) | Parallel to face grain | Perpendicular to face grain | CoreMaterials | PackingUnit

(sheets) |

||

| Momentof inertia | Sectionmodulus | Momentof inertia | Sectionmodulus | ||||||

| I(mm4/mm) | Z(mm3/mm) | I(mm4/mm) | Z(mm3/mm) | ||||||

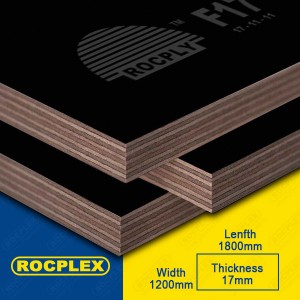

| F17 SENSO | 1800×1200 | 12, 17, 19 & 25 | 24 | 240.0 | 27.6 | 178.0 | 22.9 | Full hardwood | 40 / 43 |

| F17 SNESO | 2400×1200 | 12, 17, 19 & 25 | 32 | 240.0 | 27.6 | 178.0 | 22.9 | Full hardwood | 40 / 43 |

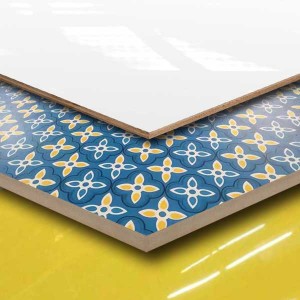

ROCPLY Special Custom HDO Film Facing Does Not Absorb Water.

And It Does Not Swell Or Shrink.

The Robust, Smooth Surface Guarantees First-class Concrete Quality Even After Many Uses.

Manufactured From High-grade Full hardwood Veneers Bonded Together With Super E0 Waterproof Adhesive, Which Has Superior Bond Strength.

The Oblique Jiont And Hot-melt Splicing Technology Are Used To Avoid Every Possible Gap.

To Ensure Excellent Hardness And Stability.

Super E0 Waterproof Adhesive. If Put In Boiling Water For 72 Hours, It Is Still Glue-sticking And Non Deformed.

The Edges 4 Times Sealed With Waterproof Paint In The Factory For Minimise Moisture Penetration.

|

1 |

Face and Back |

ROCPLY Special Custom Film |

|

2 |

Grade |

AA garde |

|

3 |

Core Materials |

Full Hardwood Core |

|

4 |

Glue Choose |

A bond Waterproof Super E0 Glue |

|

5 |

Thickness |

6-28mm(normal thickness:12mm, 15mm, 17mm, 25mm) |

|

6 |

Specification |

1800mmX1200mm, 2400mmX1200mm 1800mmX600mm , 2400mmX600mm |

|

7 |

Moisture Content |

8-14% |

|

8 |

Density |

730-780 kg/ m3 |

ROCPLY FORMPLY has been manufactured at our plant in China, for in excess of 15 years and has been used successfully in the Asia, Australia and New Zealand.

ROCPLY FORMPLY resists dilute acids and alkalines which increases the number of uses that is obtained when used with concrete.

ROCPLY FORMPLY surface is very smooth which transmits into the finish of the concrete.

ROCPLY FORMPLY is made in China from renewable plantation grown hardwood core veneers.

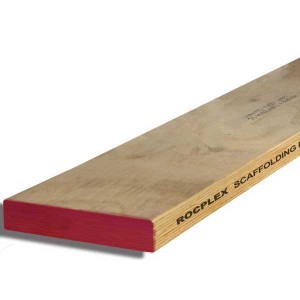

■ If put in boiling water for 72 hours, it is still glue-sticking and non-deformed

■ Physical mood is better than iron moulds and can satisfy the requirements of constructing mould,

the iron ones are easy to be deformed and can hardly recover its smoothness even after repairing

■ If used abide by the illustrations strictly, it can be reused more than 50 times,

■ Reducing the cost greatly and avoiding the disadvantages from ( rustily and erosive of iron mould)

■ Solves the problems of leaking and rough surface during constructing process

■ Particularly suitable for watering concrete project , can make the concrete surface smooth and flat

■ Realizing a higher economic profits.

| ROCPLY Fomply Save cost | ||

| Be special for phenolic glue and film | The formply can be disassembled and used repeatedly for both faces,saving 25% of the cost. | |

| Optimization for the special grade of core | ||

| Be special for adhesive | ||

| ROCPLY Fomply Shorten duration | ||

| Excellent effect of demoulding | Shorten 30% of the duration. | |

| Avoid the reconstruction of the wall | ||

| Be easy to incise and blend | ||

| ROCPLY Formply The high quality of casting | ||

| The flat and smooth faces | The faces are flat and smooth, avoiding bleeding out remains of bubbles and concrete. | |

| The structure of waterproof and breathability | ||

| The edges are polished carefully | ||

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

10-12 pallets |

22 CBM |

13000KGS |

12500KGS |

|

40 HQ |

20-27 pallets |

43 CBM |

25500KGS |

26000KGS |

We are going to dedicate ourselves to providing our esteemed buyers together with the most enthusiastically thoughtful products and services for Formply F17 Massive Selection for China Structural Plywood F17 Formply for Australia with Benchmark Certification, We glance ahead to determine a long-term organization marriage together with your esteem co-operation.

Massive Selection for China Formply F17, F17 Formply, Formply, If you need any of our merchandise, or have other products to be produced, be sure to send us your inquiries, samples or comprehensive drawings. Meanwhile, aiming to develop into an international enterprise group, we look forward to receiving offers for joint ventures and other cooperative projects.