MDF/ HDF

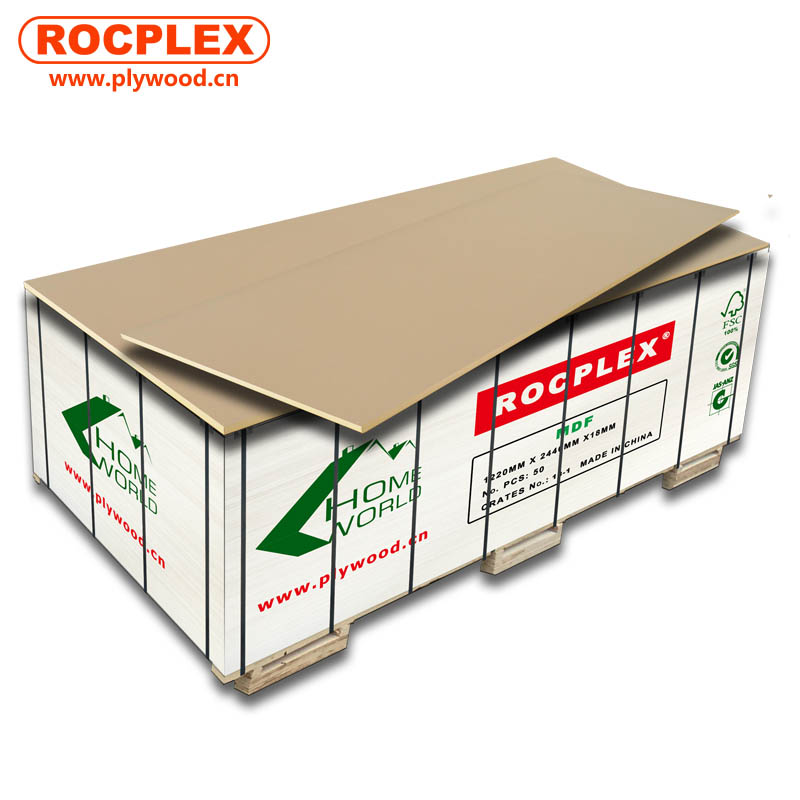

ROCPLEX ® MDF HDF offers the best in medium-density and high-density fiberboard solutions. Engineered to provide superior performance, our MDF HDF boards are perfect for a wide range of applications. Whether you're crafting fine furniture or designing modern cabinetry, ROCPLEX MDF HDF ensures a flawless finish every time.

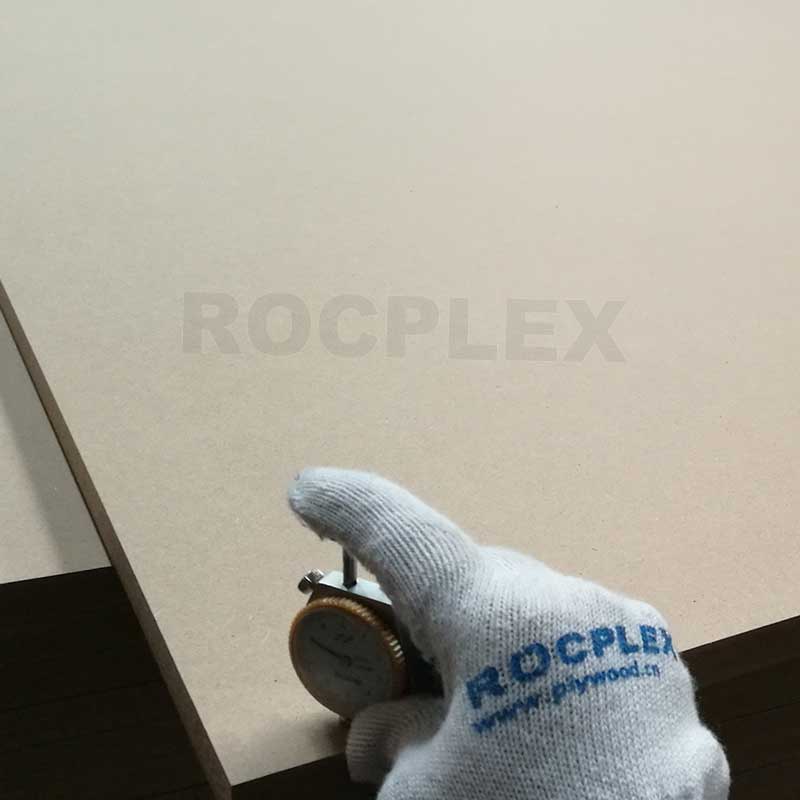

Our MDF HDF boards are manufactured using high-quality wood fibers bonded with synthetic resin under high temperature and pressure. This process results in boards that are exceptionally strong, stable, and resistant to warping. The smooth, uniform surface of MDF HDF makes it ideal for painting, veneering, or laminating.

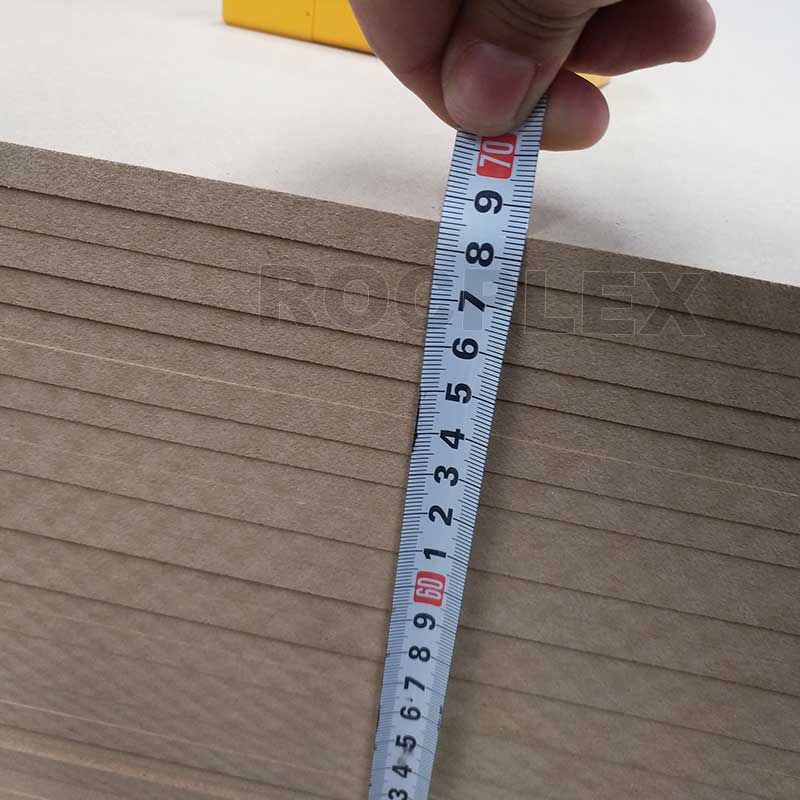

Available in various thicknesses, ROCPLEX MDF HDF boards are versatile and easy to work with. They can be cut, drilled, and shaped with standard woodworking tools, ensuring flexibility in design and execution. Moreover, our boards have excellent screw-holding capabilities, making them perfect for both structural and decorative purposes.

At ROCPLEX, we prioritize sustainability and environmental responsibility. Our MDF HDF boards are produced from responsibly sourced wood fibers and comply with strict environmental standards. This commitment ensures that our products not only meet your needs but also contribute to a greener planet.

|

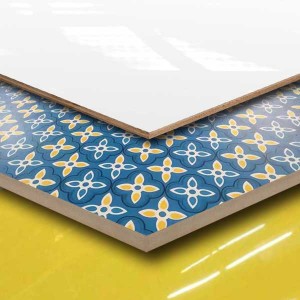

Face / Back: Raw MDF Melamine MDF Veneer MDF HPL MDF |

|

Grade: AA grade |

|

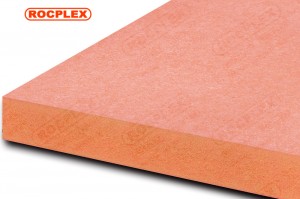

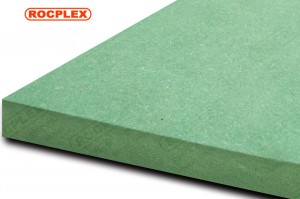

Colour: raw MDF colour, Solid colors, wood grain colors, fancy colors, stone colors |

|

Glue: E0 glue, E1 glue , E2 glue , WBP glue , MR glue |

|

Thickness: 1-28mm (normal: 3mm, 6mm, 9mm, 12mm, 15mm, 18mm, 21mm) |

|

Specification: 1220mmX2440mm, 1250mmX2500mm, 915mmX1830mm, 610mmX2440mm, 610mmX2500mm |

|

Moisture Content: below 8% |

|

Density: 660 / 700 / 720 / 740 / 840 / 1200 kg/m3 |

■ Superior Strength: ROCPLEX MDF HDF boards are engineered for maximum durability and stability.

■ Smooth Surface: The uniform surface is ideal for painting, laminating, and veneering.

■ Versatility: Suitable for a wide range of applications, from furniture to industrial uses.

■ Easy Machinability: Can be easily cut, drilled, and shaped with standard woodworking tools.

■ Excellent Screw-Holding Capacity: Ensures strong, secure assemblies in all projects.

■ Sustainable Production: Made from responsibly sourced wood fibers, contributing to environmental sustainability.

■ Variety of Thicknesses: Available in multiple thickness options to meet diverse project needs.

■ Cost-Effective: Provides a high-quality, economical alternative to solid wood.

■ Reliable Performance: Resistant to warping and deformation, ensuring long-lasting results.

■ Eco-Friendly: Complies with strict environmental standards for a greener choice.

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

8 pallets |

22 CBM |

16500KGS |

17000KGS |

|

40 HQ |

16 pallets |

38 CBM |

27500KGS |

28000KGS |

■ ROCPLEX MDF HDF is suitable for a wide range of applications. It is extensively used in the manufacture of furniture, offering a cost-effective alternative to solid wood without compromising on quality. Its smooth surface and ease of machining make it perfect for creating intricate designs and detailed finishes.

■ In the realm of cabinetry, MDF HDF is unparalleled. Its stability and uniformity provide an excellent substrate for laminates, veneers, and paints, resulting in beautiful, durable cabinets. Additionally, MDF HDF is widely used in the production of moldings, paneling, and shelving, providing a versatile solution for various interior design projects.

■ Our MDF HDF boards are also ideal for industrial applications, such as the production of doors, partitions, and flooring underlayment. Their strength and durability ensure long-lasting performance, even in demanding environments.

MDF is manufactured from wood fibres, mixed with resin and waxes which are then hot pressed to the required thickness. These wood fibres are sourced from environmentally friendly forest thinnings, recycled wood/pallets, and sawdust. All our suppliers provide FSC and PEFC certification.

All dust can be harmful if inhaled or ingested, MDF dust is no exception. Correct PPE such as dust masks and goggles should be worn as a matter of routine. Workshop machines should be fitted with appropriate dust extraction equipment. If not in a workshop environment then MDF should be worked in a well ventilated area. The use of a respirator fitted with P2 filter units is highly recommended.

Choose ROCPLEX MDF HDF for your next project and experience the superior quality and versatility it offers. Contact us today to learn more about our MDF HDF boards and how they can meet your specific needs. Let ROCPLEX be your trusted partner in achieving outstanding results.