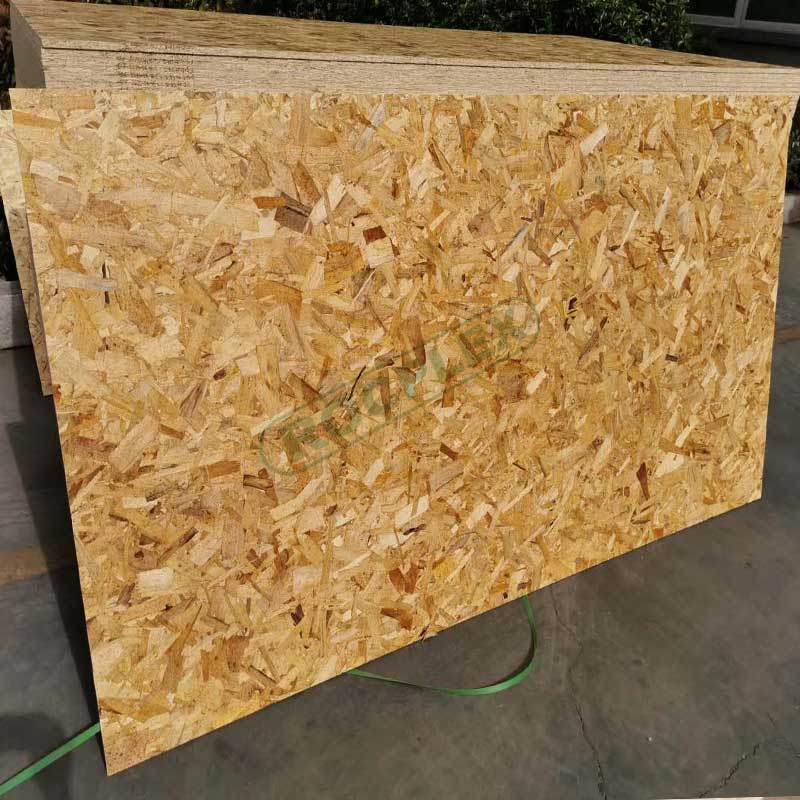

OSB (OrientedStrandBoard) is a type of engineered wood similar to particle board, by adding layers of wood strands (flakes) in a specific orientation that form a binder and then compress the wood.

It was invented in 1963 by Armin Elmendorf of California. OSB may have a rough and variegated surface, with individual strips approximately 2.5 cm x 15 cm (1.0 x 5.9 in) placed unevenly across each other, and in a variety of types and thicknesses.

Purpose of OSB

OSB is a material with good mechanical properties, making it particularly suitable for load-bearing applications in construction.

It is now more popular than plywood, accounting for 66% of the structural panel market. The most common uses are as sheathing for walls, floors and roof decks.

For exterior wall applications, the panels can be laminated with a radiant barrier on one side; this simplifies installation and improves the energy performance of the building envelope. OSB is also used in furniture production.

Manufacturing of OSB Boards

Types of adhesive resins used by OSB include: urea-formaldehyde (OSB type 1, non-structural, non-waterproof); isocyanate-based adhesives (or PMDI polymethylene diphenyl diisocyanate-based) in interior areas with melamine-urea-formaldehyde or phenol-formaldehyde Resin glue on the surface (OSB type 2, structural, surface waterproofing); phenolic resin (OSB type 3 and 4, structural type, for wet and outdoor environments).

The layers are formed by shredding the wood into strips that are screened and then oriented on a belt or wire mesh. The cushions are manufactured on a molding line. The wooden slats of the outer layer are aligned with the strength axis of the panels, while the inner layer is vertical. The number of layers placed depends in part on the thickness of the panel, but is limited by the equipment installed at the manufacturing site. The thickness of the individual layers can also vary to provide different finished panel thicknesses (typically, a 15 cm (5.9 in) layer will yield a 15 mm (0.59 in) panel thickness). The mat is placed in a hot press to compress the sheets and bond them by thermally activating and curing the resin that has been coated on the sheets. The individual panels are then cut from the mat to finished size. Most of the world's OSB is manufactured in large production facilities in the United States and Canada.

Materials other than wood have been used to produce products similar to OSB. Oriented structure straw board is an engineering board made by splitting the straw, adding P-MDI adhesive, and hot pressing the straw layer in a specific direction. Particleboard can also be made from bagasse.

#OSB #OSB3 #PB #particleboard

Post time: Sep-14-2022