Revolutionize Your Construction Projects with ROCPLEX Plastic Plywood

In recent years, there has been a growing interest in plastic plywood as a durable, versatile, and eco-friendly building material. Traditional plywood, made from layers of thin wood veneer glued together, has long been the go-to material for construction projects, but it has some limitations. Plywood is susceptible to moisture, warping, and decay, which can compromise its structural integrity and shorten its lifespan. Plastic plywood, on the other hand, is resistant to water, termites, rot, and decay, making it a more durable and reliable alternative to traditional plywood.

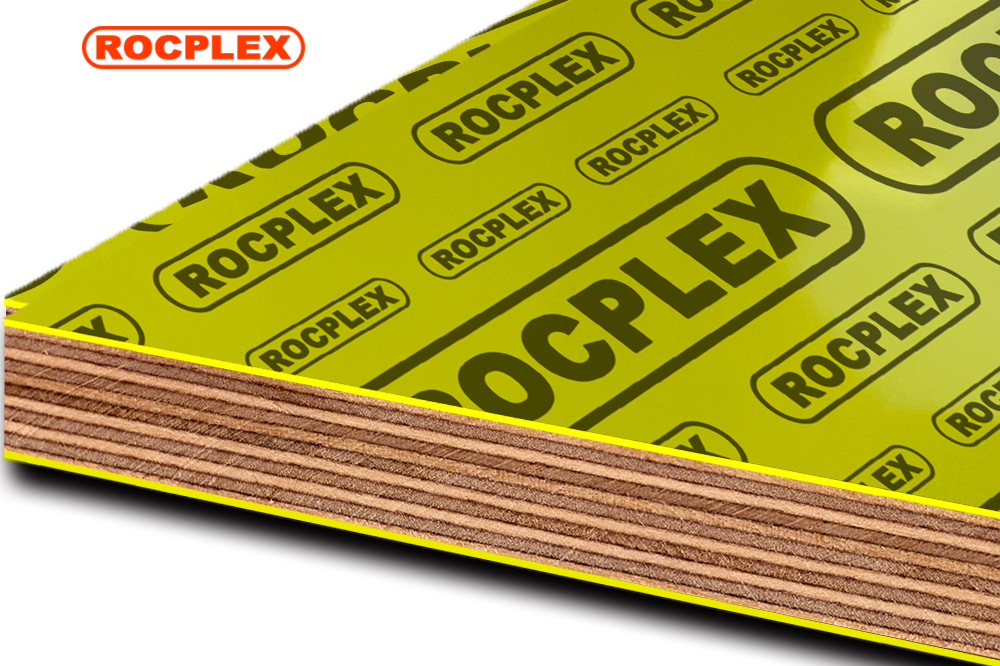

One of the leading manufacturers of plastic plywood is ROCPLEX. ROCPLEX is a leading producer of plastic plywood sheets, which are made from a combination of high-density polyethylene (HDPE) and recycled plastic. The result is a lightweight, strong, and eco-friendly material that can be used for a variety of construction applications.

In this article, we'll explore the benefits of ROCPLEX plastic plywood, including its durability, versatility, affordability, and sustainability. We'll also compare ROCPLEX plastic plywood to other types of plastic plywood and traditional plywood, and highlight some of the ways in which it can be used in construction projects.

Benefits of ROCPLEX Plastic Plywood

Durability

ROCPLEX plastic plywood is highly durable and resistant to water, termites, rot, and decay. Unlike traditional plywood, which can warp and delaminate when exposed to moisture, ROCPLEX plastic plywood maintains its structural integrity in wet or damp conditions. This makes it an ideal material for outdoor applications, such as decking, fencing, and signage, as well as indoor applications, such as bathroom and kitchen cabinets, furniture, and wall paneling.

Versatility

ROCPLEX plastic plywood is highly versatile and can be used in a wide range of construction applications. It can be cut, drilled, and shaped just like traditional plywood, but it is much lighter and easier to handle. This makes it an ideal material for DIY projects, as well as for professional builders who need a material that is easy to work with and can be adapted to different design specifications.

Affordability

ROCPLEX plastic plywood is an affordable alternative to traditional plywood and other types of plastic plywood. It is priced competitively and is often less expensive than other plastic plywood brands, while still providing the same level of durability and performance. This makes it an attractive option for builders who want to save money on construction materials without compromising on quality.

Sustainability

ROCPLEX plastic plywood is an eco-friendly material that is made from recycled plastic and is 100% recyclable. It is a sustainable alternative to traditional plywood, which is made from trees that are often harvested unsustainably. By choosing ROCPLEX plastic plywood, builders can help to reduce the demand for virgin wood products and support a more sustainable construction industry.

Comparing ROCPLEX Plastic Plywood to Other Types of Plastic Plywood

ROCPLEX plastic plywood is just one of several brands of Plastic Plywood, plastic plywood 4 x 8, Pvc Plywood, ROCPLEX plastic plywood available on the market. Other popular brands include PVC plywood, HDPE plywood, and polycarbonate plywood. Each of these types of plastic plywood has its own unique properties and advantages, but ROCPLEX plastic plywood is widely regarded as one of the best options due to its combination of durability, versatility, affordability, and sustainability.

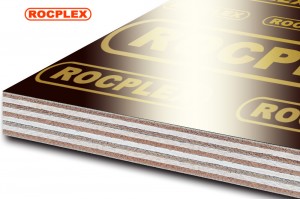

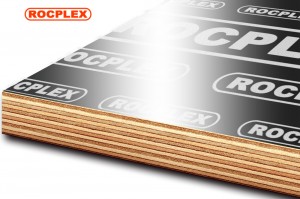

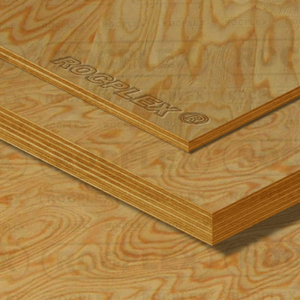

Manufactured From High-grade Birch Veneers Bonded Together With Super E0 Waterproof Adhesive, Which Has Superior Bond Strength.

The oblique jiont and hot-melt splicing technology are used to avoid every possible gap.

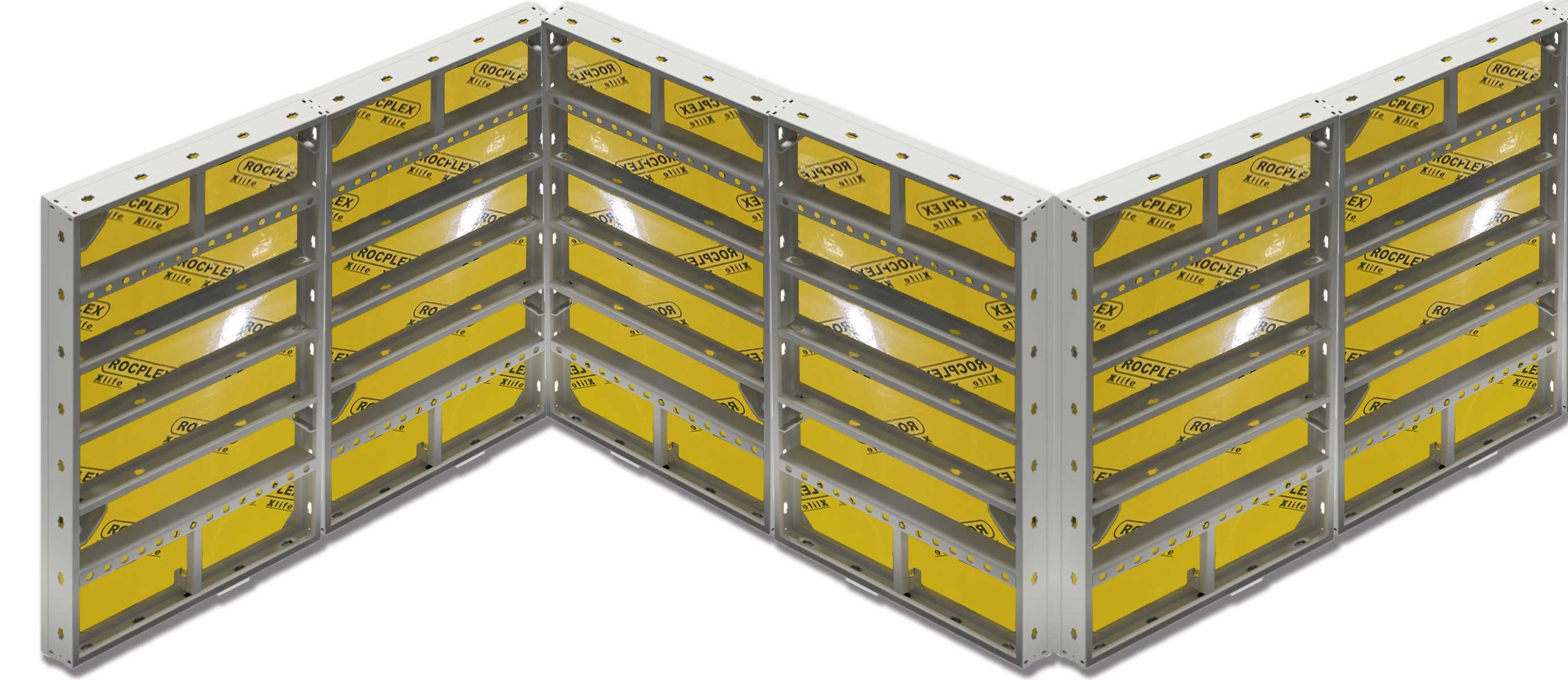

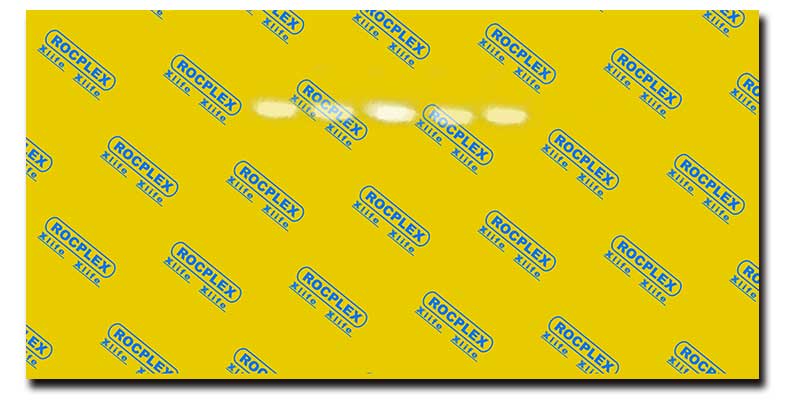

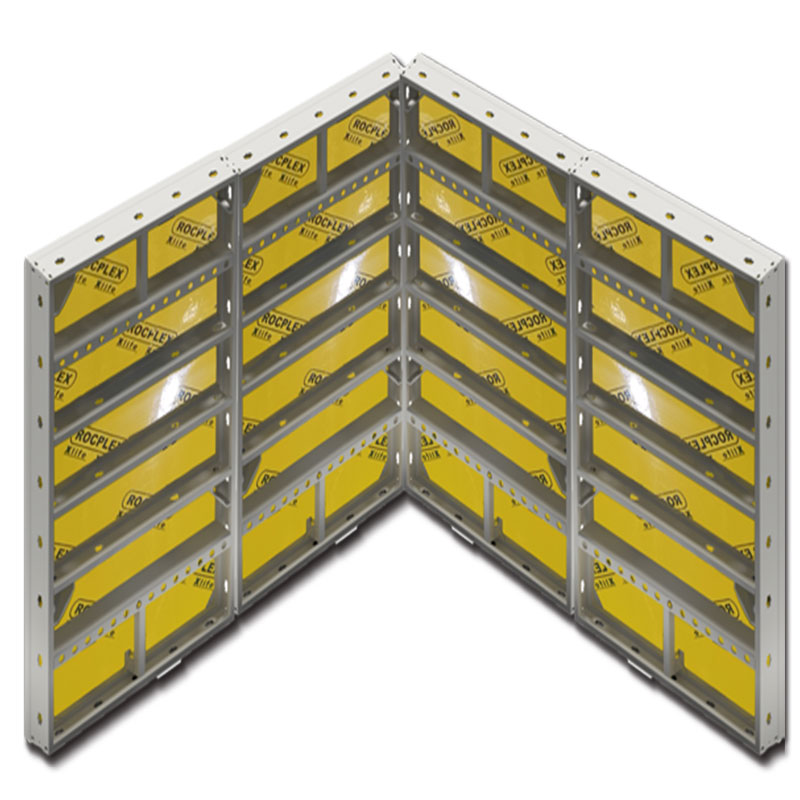

ROCPLEX Xlife formply plywood for strong, stable, concrete formwork

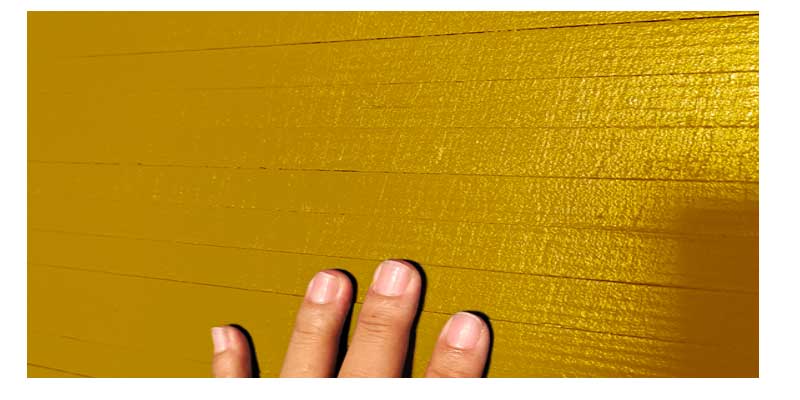

ROCPLEX Organic Toughened Plastic Facing Does Not Absorb Water.

It Does Not Swell Or Shrink. The Robust, Smooth Surface Guarantees First-class Concrete Quality Even After Many Uses.

Given Optimum Conditions Of Use And Correct Handling, Max Up To 350 Use Cycles (guide Value) In Frame Formwork Can Be Achieved.

Due To Their Durability, The Rocplex Xlife Plywood Sheet Are A Good For Formwork Applications.

Manufactured From High-grade Birch Veneers Bonded Together With Super E0 Waterproof Adhesive, Which Has Superior Bond Strength.

The Oblique Jiont And Hot-melt Splicing Technology Are Used To Avoid Every Possible Gap.

To Ensure Excellent Hardness And Stability.

Super E0 Waterproof Adhesive. If Put In Boiling Water For 72 Hours, It Is Still Glue-sticking And Non Deformed.

The Edges 3 Times Sealed With Waterproof Paint In The Factory For Minimise Moisture Penetration.

|

1 |

Face and Back |

1.0mm plastic double side |

|

2 |

Grade |

AA garde |

|

3 |

Core Materials |

Full Birch Core |

|

4 |

Glue Choose |

Waterproof Super E0 Glue |

|

5 |

Thickness |

6-28mm(normal thickness:12mm, 15mm, 18mm, 21mm) |

|

6 |

Specification |

1220mmX2440mm,1250mmX2500mm,1200mmX2400mm ,1200mmX1800mm |

|

7 |

Moisture Content |

8-14% |

|

8 |

Density |

730-780 kg/ m3 |

|

9 |

Cycle Life |

More than 350 times |

If put in boiling water for 72 hours, it is still glue-sticking and non-deformed.

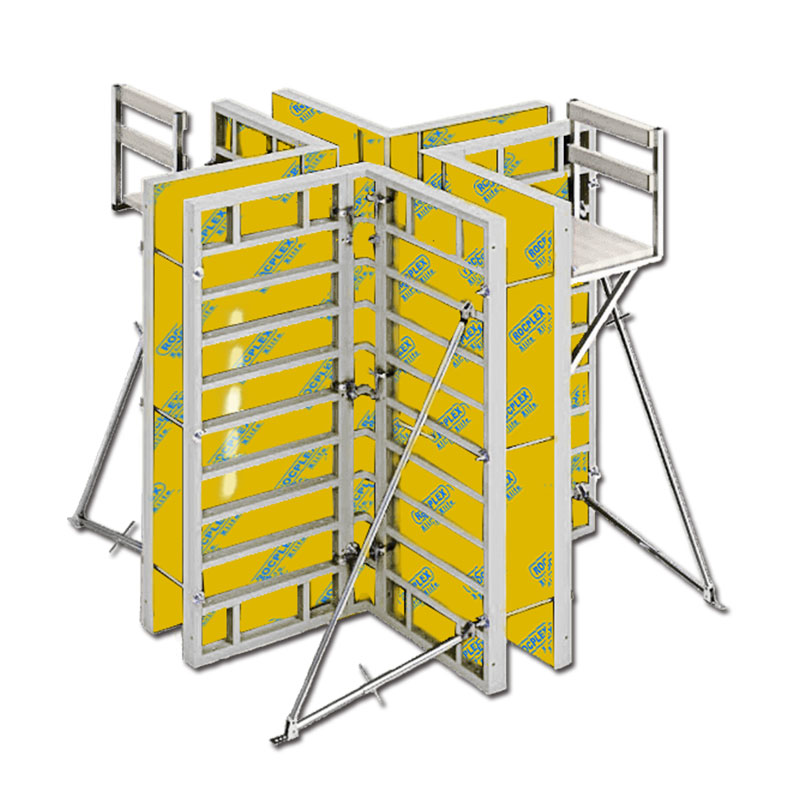

Physical mood is better than iron moulds and can satisfy the requirements of constructing mould,the iron ones are easy to be deformed and can hardly recover its smoothness even after repairing.

If used abide by the illustrations strictly, it can be reused more than 350 times.

Reducing the cost greatly and avoiding the disadvantages from ( rustily and erosive of iron mould).

Solves the problems of leaking and rough surface during constructing process.

Particularly suitable for watering concrete project ,can make the concrete surface smoonth and flat.

|

ROCPLEX Xlife Formwork Plywood Save cost |

||

|

|

Be special for phenolic glue and film |

The film faced plywood can be disassembled and used repeatedly for both faces,saving 25% of the cost. |

|

|

Optimization for the special grade of core |

|

|

|

Be special for adhesive |

|

|

ROCPLEX Xlife Formwork Plywood Shorten duration |

||

|

|

Excellent effect of demoulding |

Shorten 30% of the duration. |

|

|

Avoid the reconstruction of the wall |

|

|

|

Be easy to incise and blend |

|

|

ROCPLEX Xlife Formwork Plywood the high quality of casting |

||

|

|

The flat and smooth faces |

The faces are flat and smooth, avoiding bleeding out remains of bubbles and concrete. |

|

|

The structure of waterproof and breathability |

|

|

|

The edges are polished carefully |

|

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

8 pallets |

22 CBM |

13000KGS |

12500KGS |

|

40 HQ |

18 pallets |

53 CBM |

27500KGS |

28000KGS |

|

|

|