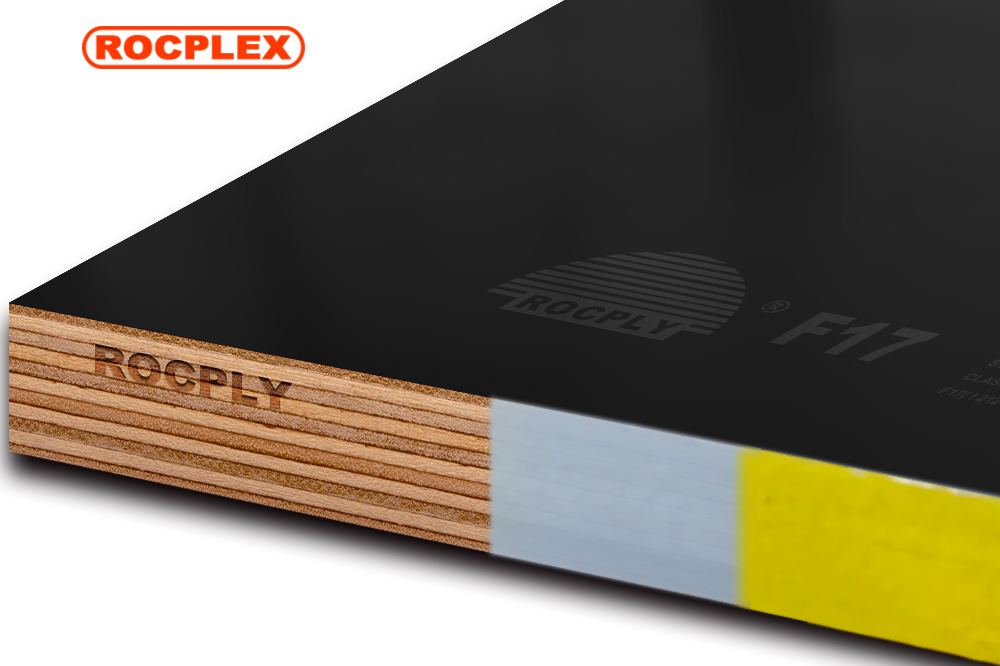

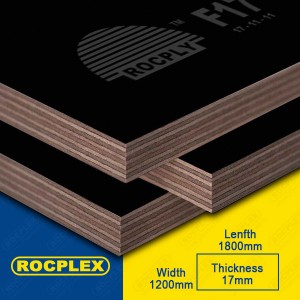

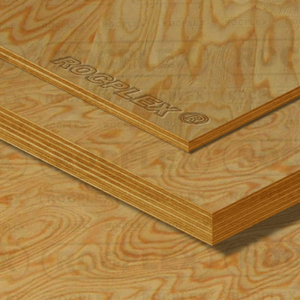

Formply F17 1800 x 1200 x 17mm Formwork Plywood AS 6669 Certified

ROCPLY ® Formply F17 in the size of 1800 x 1200 x 17mm is a high-performance and cost-effective formwork material that offers exceptional value for its cost.

ROCPLY ® is the only F17 formply who holds both Benchmark and Certmark dual certification testament to its high standards of quality and durabilityIts recognition as a top-quality formply F17 product.

ROCPLY F17 Formply is a high-quality formwork plywood that is specifically designed for use in Australia and New Zealand high-end projects concrete formwork applications. The plywood is manufactured using high-grade full hardwood veneers that are bonded together with a custom-made super E0 waterproof adhesive, providing superior bonding strength that makes the plywood strong and stable.

The manufacturing process of ROCPLY F17 Formply utilizes oblique joint and hot-melt splicing technology to avoid any possible gaps between the veneers, ensuring the plywood is solid, durable, and reliable. It is subjected to a rigorous three-tier quality control program that includes detailed manufacturing specifications adhered to by trained staff, in-house testing on key quality requirements, and independent grading, testing, and certification by Certemark International (CMI) and the British Standards Institution (BSI). This ensures that the plywood meets the required quality standards for use in concrete formwork.

ROCPLY F17 Formply is manufactured using certified Forest Stewardship Council (FSC) veneer from sustainable forests, reflecting the company's commitment to responsible and sustainable forestry practices. This makes ROCPLY F17 Formply an ideal choice for contractors and builders who are concerned about sustainable building practices.

ROCPLY F17 Formply is a reliable and cost-effective choice for concrete formwork applications. Its use of high-grade materials, superior bonding strength, and rigorous quality control processes ensures that the plywood is strong, stable, and durable, making it an ideal choice for construction projects of all types and sizes. Whether you are building a foundation, wall, column, or bridge, ROCPLY F17 Formply is a reliable and cost-effective choice that you can count on to deliver high performance and exceptional value.

| Stress Grade | Sheet Size (mm) | Thicknesses (mm) | Weight (kg/sheet) | Parallel to face grain | Perpendicular to face grain | Core

Materials |

Packing

Unit (sheets) |

||

| Momentof inertia | Sectionmodulus | Momentof inertia | Sectionmodulus | ||||||

| I(mm4/mm) | Z(mm3/mm) | I(mm4/mm) | Z(mm3/mm) | ||||||

| F17 SENSO | 1800×1200 | 12, 17, 19 & 25 | 24 | 240.0 | 27.6 | 178.0 | 22.9 | Full hardwood | 40 / 43 |

| F17 SNESO | 2400×1200 | 12, 17, 19 & 25 | 32 | 240.0 | 27.6 | 178.0 | 22.9 | Full hardwood | 40 / 43 |

Surfaces

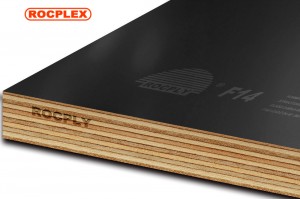

The special HDO (High Density Overlay) film facing used in ROCPLY F17 FormPly provides a super smooth surface designed to resist water absorption and maintain its dimensional stability, that helps prevent the adhesion of concrete during the pouring and setting process. This makes it a durable and reliable choice for concrete formwork applications, even when exposed to moisture or humidity.

Structure

ROCPLY F17 made from high-grade full-hardwood veneers , miter joint design, and hot-melt splicing technology make ROCPLY F17 FormPly a top product known for its strength and durability, able to withstand the weight and pressure of heavy objects and is less prone to bending, warping or breaking. This helps ensure that the concrete form retains its integrity even after multiple uses.

Bonding

ROCPLY F17 FormPly is made with A-bond Super E0 waterproof adhesive, which is a high-quality adhesive that provides superior bonding strength and water resistance. ROCPLY Laboratory boiling water test data far exceeds 90 hours, it still maintain its glue-sticking properties and will not become deformed. This is a testament to the adhesive used in the ROCPLY manufacturing process, which is able to withstand extreme conditions and remain strong and stable.

Sealing

ROCPLY F17 FormPly is designed with 4 Times sealed edges that are painted with waterproof paint in the factory to minimize moisture penetration. The sealing design helps to prevent moisture and water from penetrating the plywood, which can help to prolong its lifespan and maintain its structural integrity.

|

1 |

Face and Back |

ROCPLY Special Custom Film |

|

2 |

Grade |

AA garde |

|

3 |

Core Materials |

Full Hardwood Core |

|

4 |

Glue Choose |

A bond Waterproof Super E0 Glue |

|

5 |

Thickness |

6-28mm(normal thickness:12mm, 15mm, 17mm, 25mm) |

|

6 |

Specification |

1800mmX1200mm, 2400mmX1200mm 1800mmX600mm , 2400mmX600mm |

|

7 |

Moisture Content |

8-14% |

|

8 |

Density |

730-780 kg/ m3 |

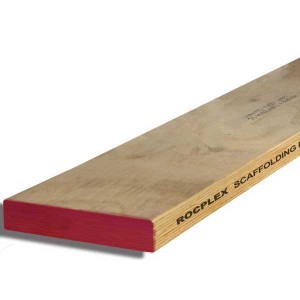

ROCPLY Formply Factory has been manufacturing F17 formply in China for over 15 years and has established a good reputation of use in Asia, Australia, and New Zealand. ROCPLY Formply is a reliable and durable formwork material that offers a range of benefits for contractors and builders.

One of the key advantages of ROCPLY Formply is its resistance to dilute acids and alkalines, which makes it a durable and reliable choice for use in concrete formwork applications. This resistance to chemicals ensures that the plywood can withstand exposure to the chemicals commonly used in the construction of concrete structures.

Another advantage of ROCPLY Formply is its smooth surface, which helps to create a smooth and even finish for the poured concrete. The smooth surface is achieved through a manufacturing process that ensures the plywood is made to high standards of quality and consistency.

ROCPLY Formply is manufactured in China from renewable plantation-grown hardwood core veneers. This makes it an environmentally friendly choice that helps to reduce the impact of construction on natural resources.

The fact that ROCPLY Formply can withstand exposure to boiling water for 90 hours and still maintain its bond strength and shape is a testament to its high-quality construction and durable materials. Additionally, ROCPLY Formply F17 can be reused more than 50 times in many concrete engineering projects, which reduces the overall cost of construction.

ROCPLY Formply is a reliable and high-performance formwork material that offers excellent value for its cost. Its durability, smooth surface, and ability to resist chemicals and water make it a popular choice among contractors and builders around the world. Whether you are building a foundation, wall, column, or bridge, ROCPLY Formply is a durable and versatile choice that you can count on to deliver high performance and exceptional value.

| ROCPLY Fomply Save cost | ||

| Be special for phenolic glue and film | The formply can be disassembled and used repeatedly for both faces,saving 25% of the cost. | |

| Optimization for the special grade of core | ||

| Be special for adhesive | ||

| ROCPLY Fomply Shorten duration | ||

| Excellent effect of demoulding | Shorten 30% of the duration. | |

| Avoid the reconstruction of the wall | ||

| Be easy to incise and blend | ||

| ROCPLY Formply The high quality of casting | ||

| The flat and smooth faces | The faces are flat and smooth, avoiding bleeding out remains of bubbles and concrete. | |

| The structure of waterproof and breathability | ||

| The edges are polished carefully | ||

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

10-12 pallets |

22 CBM |

13000KGS |

12500KGS |

|

40 HQ |

20-27 pallets |

43 CBM |

25500KGS |

26000KGS |

Upgrade your construction projects with ROCPLY Formply F17 1800 x 1200 x 17mm. Contact us today to learn more about how this high-strength, AS 6669 certified plywood can meet your formwork needs. Ensure superior performance and reliability on your next project with ROCPLY.